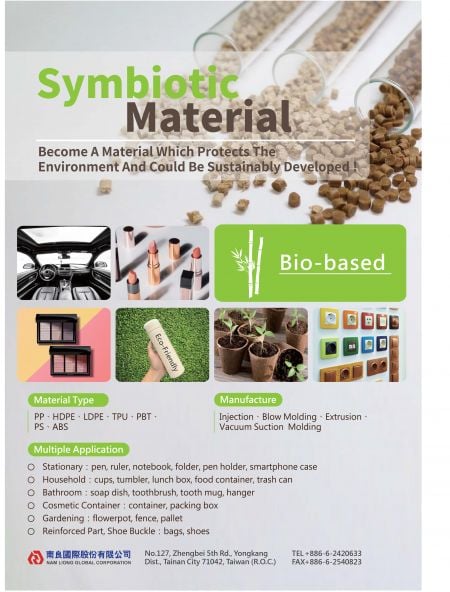

Eco Friendly Material

Reduced Plastic And Environment Friendly Polymer Materials

Bio-based Resin reduces plastic and carbon

Our Bio-based resin, NL-WPC-master batch™ Series, is pure natural organic materials. As our main appeal to help plastic products factories and provide effective solutions to the international issues of reducing plastic and carbon, Nam-Liong continues to innovate and associate with the topics of "plants" and "environmental protection" from different sources such as recycled pallets, rice straws and finally choose Mengzong bamboo as the main raw material.

Banboo is a good solution for carbon reduction

Generally, forest trees take at least 30 to 40 years to become timber, and the carbon dioxide adsorption capacity per hectare (ha) per year is 7.45 to 14.9 metric tons (mt). Compared with forest trees, bamboo can be used in only four years. In addition to the carbon sequestration capacity of bamboo forests is stronger than that of wood, processed products also have carbon fixation function. Therefore, governments around the world who are committed to improving climate warming have a lot to do with bamboo forest management.

Domestic scholars have studied four main bamboo species in Taiwan, and the best one is Mengzong bamboo. A five-year-old osmanthus bamboo can fix 6.2 kgs of carbon dioxide, calculated at 18,000 plants per ha, and 22.32 tons of carbon per year; a five-year-old bamboo can fix 29.6 kg of carbon dioxide, calculated at 8,000 plants per ha, 47.36 tons of carbon sequestration per year.

value of its highest carbon sequestration ability and tough structure, but also because "bamboo" has the symbolic meaning of "vitality" and "noble character", which complements the spirit of Nam-Liong, respecting life and caring for the environment. In addition to reducing the use of plastic raw materials, the factory adds "green symbiotic colloidal particles" to the production process. The finished product has a unique bamboo scent, adding product features. While contributing to environmental protection, it also enhances the taste of users.

NL-WPC-master batch™ Series obtains USDA certificate

Our Bio-based resins, NL-WPC-master batch™ Series, obtains USDA BioPreferred® (also known as organic certification) from the United States Department of Agriculture in April 2019, and the BETA biomass content certification number: 40713151987199340. The test result shows that the bio-based carbon content (Bio-based Carbon Content) can reach 46%.

"Biomass carbon content" is used to display the carbon source of the raw materials used in the product, indicating the percentage of carbon sourced from "natural" (plant or animal derived) and "synthetic" (petrochemical) sources, between 0-100% The value between the two indicates the percentage mixing degree of both petrochemical and natural components. The higher the measurement value, the higher the proportion of natural components in the material. All experimental assays were performed at the Miami Laboratory, Florida, and were tested using the laboratory's own accelerator mass spectrometry (Isotope ratio mass spectrometry).

You can click to view the product properties (red color letter) below, or you can make them according to your needs. Welcome to leave a message below or call 06-2420633, let us further discuss and test the product suitable for you.

Features

- Have the pros of plastic and woods, overcome the limitations of materials such as the low strength of wood and large variability.

- Overcome the defects of low elasticity of organic materials, improve the physical and mechanical properties and processing properties of materials, reduce costs and expand the application range of materials, enhance the added value and application range of materials

- Enhance the added value and application range of materials, which can be used in construction, decoration, transportation and packaging... and other product fields.

Product Collections

| Range of applications | Processing condition |

Stationery,Household items, Bathroom products,Cosmetic bottle, Shoes… | Manufacturing conditions: 190 ℃ max. 5 liters max. | |

Manufacturing conditions: 170 ℃ max. 5 liters max. | ||

Manufacturing conditions: 160 ℃ max. 5 liters max. |

Applications

Stationery, Household items, Bathroom products, Cosmetic bottles,Shoes…

Eco Friendly Material - Reduced Plastic And Environment Friendly Polymer Materials | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

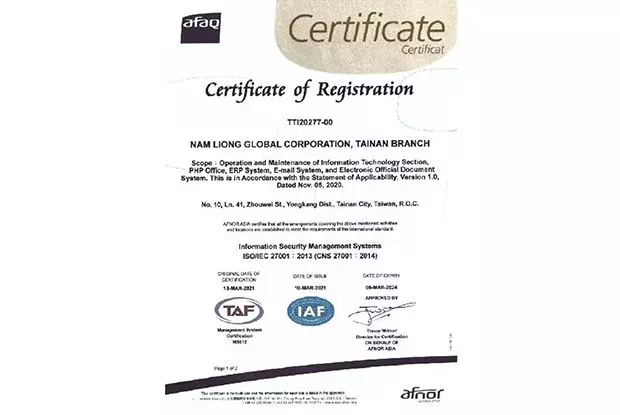

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Eco Friendly Material, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.