Chloroprene Rubber Foam

Nam Liong SEAMATE® Chloroprene Rubber Foam material is the closed-cell foam with good elasticity....

Styrene butadiene rubber (SBR) Sponge

Nam Liong SEAMATE® Styrene Butadiene Rubber Sponge is the closed-cell foam with the characteristics...

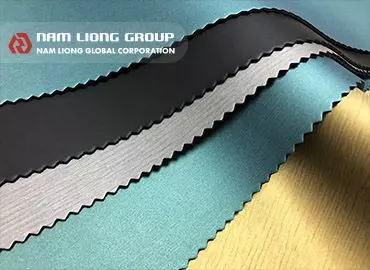

Oeko-Tex standard 100 Certificated Rubber Foam Laminate

Oeko-Tex standard 100 Certificated Rubber Foam Laminate has got Oeko-Tex Standard 100 certification...

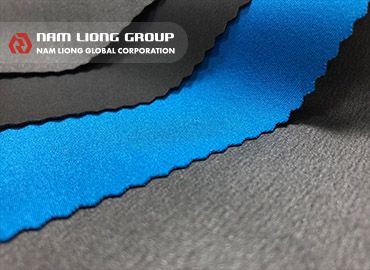

Super Thin Rubber Foam Laminate

Super Thin Rubber Foam (neoprene) Laminate is the material with multi-layer and multi-function....

Super Smooth Wetsuit Material

Super Smooth Wetsuit Material is the surface treatment process on Chloroprene Rubber sponge...

Embossed Rubber Foam

Rubber foam can be embossed to enhance the surface strength and the performance of anti-slip....

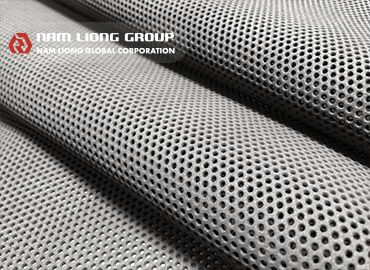

Breathable Rubber Foam

After the perforation treatment, the closed-cell rubber sponge results in upper the breathability;...

UL-1191 Life Vest Material

UL approved life vest neoprene material is the fabric-laminated neoprene rubber sponge that...

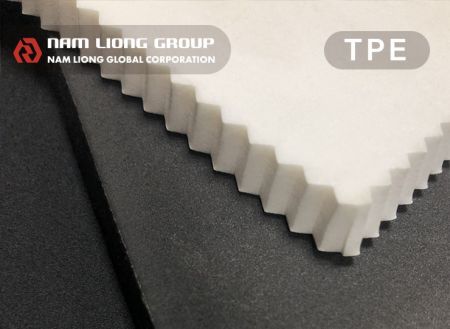

Thermoplastic Elastomer Foam

Thermoplastic elastomer (TPE) foam is the sponge with closed-cell structure. The elongation...

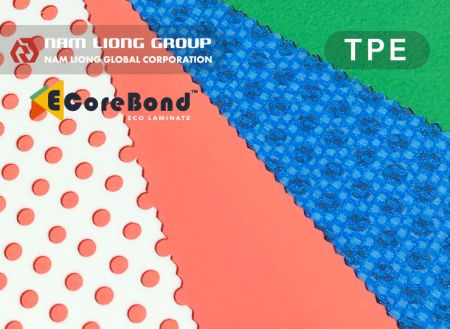

Thermoplastic Elastomer Laminate

What Thermoplastic Elastomer Laminate provides is more than just the foam. ECoreBond™ is the thermoplastic...

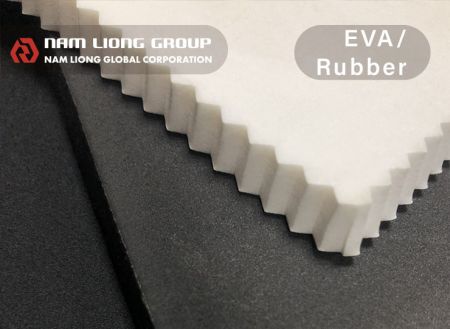

EVA/rubber Foam

EVA/rubber foam is the closed-cell sponge made of Ethylene-Vinyl Acetate and rubber. The rubber...

Bio-based Rubber Sponge

Nam Liong BIO-II™ Bio-based Rubber Sponge is the closed-cell sponge made from the renewable...

.jpg?v=83e3ef85)