Eco-friendly Membrane

Thermoplastics, Environmentally Friendly Film

In recent years, the world has begun to pay attention to ESG themes, environment, society, and sustainable management of the company. We introduce DuPont biomass raw materials and R&D results films from the principles of strict supervision, recycling and reuse, and obtain GRS, and continue to operate at a global low level. Advances in carbon and recycled materials, deepens green, sustainable and environmentally friendly materials, and re-innovates.

2016 Become bluesign® system partner(Nanxiong Jiaxing China)

2018 Bluesign® approved (Nanxiong Jiaxing China)

2019 Pass Oeko-Tex Class I (TP001 159432)

2020 Pass Global Recycled Standard (GRS) certificate

2022 Ecomate® DPA1SE 27% BIO content by BETA Lab with USDA certification

2023 TPU membrane TS102A phenolic yellowing resistance up to 4.0 grade(ASTM G155-21)

2023 Become bluesign® system partner (Namliong Taiwan)

2024 Bluesign® approved (Namliong Taiwan)

2024 HIGG completion (Namliong Taiwan)

Please continue to go to Check the introduction of film materials below, there are more detailed content to help you find suitable film materials.

Ingredients | Environmental advantages | Applications | |

Bio-based membrane | Biomass | Reduce dependency for Oil and carbon emissions | Jackets、Soft shells, Jerseys, casual jackets, windbreakers, protective clothing, skiwear, injection molding insoles, waterproof shoe liners |

GRS membrane | Recycled TPU | Recycle and reuse scrap. Reduce plastic waste and carbon emissions | |

TPEE | TPEE Thermoplastic Polyester Elastomer | Recyclable mono-material after laminating with Poly fabric | Functional outerwear, Jackets、Soft shells, ready-to-wear, footwear, aprons, workwear, gloves, bedding |

PP membrane | PP | Energy-efficient in producing | Garment, Functional outerwear, windbreaker, raincoat, jacket, antifreeze overalls, shoe materials |

Applications

- Sportswear, Windbreaker Jacket, Car Cover, Sleeping Bag.

TPAE MEMBRANE

Thermoplastic Polyamide Elastomer Film

The TPAE film Namliong developed can be laminated with Nylon fabric to form a mono-material...

DetailsTPEE MEMBRANE

TPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

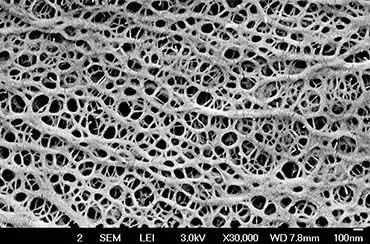

MICROPOROUS MEMBRANE

Microporous Breathable PP Film, Polyethylene

The microporous film is breathable by imitating the perspiration of the human body. There are as many...

DetailsBIO-BASED MEMBRANE

BioBased TPU Film, Thermoplastic Polyurethane TPU, GRS Certified Film, Thermoplastics, Environmentally Friendly Film, Eco-Family, BIO TPEE

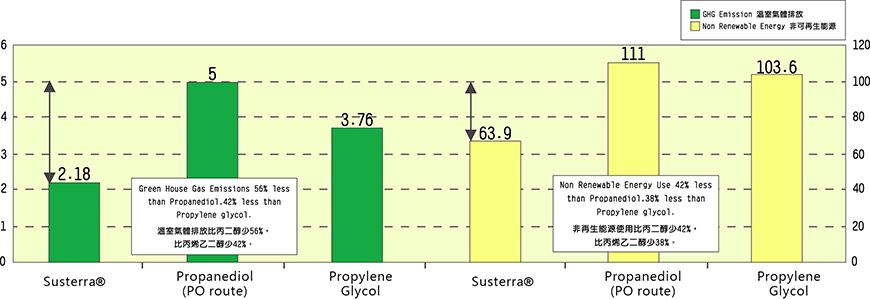

ECOMATE® biofilm integrates COVATION DuPont's Susterra® biomass-derived materials into its product...

DetailsGRS CERTIFIED MEMBRANE

GRS Certified Film , Global Recycle , Environmentally Friendly Film, Eco-Family

Global Recycled Standard (GRS) is an international, voluntary, and complete product standard...

DetailsEco-friendly Membrane - Thermoplastics, Environmentally Friendly Film | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Eco-friendly Membrane, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.