TPAE MEMBRANE

Thermoplastic Polyamide Elastomer Film

Nylon membrane, TPAE membrane

The TPAE film Namliong developed can be laminated with Nylon fabric to form a mono-material that is more convenient to recycle and reuse, with no need to spend additional time and cost to decompose recycled waste of different materials. The recycled waste can be reused to make other plastic stuff, such as buckles, plastic pallet and, flower pots. In sustainability, we do our part to help the world reduce dependence on petrochemicals and carbon emissions.

TPAE is a nylon elastomer composed of hard segments and soft segments, so it has a wide hardness and processing range. TPAE still has good impact resistance and resilience in low-temperature environments, and can be used for high-performance and high-end sporting goods such as shoes and cold-resistant ski boots. In terms of environmental protection, like TPU film, there is no plasticizer in the manufacturing process, so it is also a green material that is quite promising in recent years.

The TPAE film Namliong developed is composed of nylon hard segments, that can be laminated with Nylon fabrics to form a mono-material.

The goods using mono-material are more convenient to recycle and reuse, which not only reduces one recycling process, but also does not require additional time and cost to decompose recycled waste of different materials. The recycled products can be crushed, kneaded, and re-granulated to make other plastic injection products, such as buckles, plastic pallets, flower pots, buckets, plastic shells for electronic products, or shells for daily necessities.

The popularity of fast fashion clothing has led to the accumulation of tens of thousands of tons of waste clothes every year, and it is difficult to recycle because it contains various materials or blended fabrics. Now, you can choose a mono-material with the concept of sustainability. Do your best to reduce dependence on petrochemicals and reduce carbon emissions.

Product Collections

<!doctype html>

UREAMAX® | |

Without PE carrier | |

NL4412 | Feature |

| *S: Clear(matt) color, WS: White color. * Above data for reference only. Actual data might be different. Depend on actual thickness, color, design. | |

Applications

- sneakers, ski boots, windproof and cold-resistant coat, BCD Inflatable Diving Bag

- Related Products

TPEE MEMBRANE

DetailsTPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

BIO-BASED MEMBRANE

BioBased TPU Film, Thermoplastic Polyurethane TPU, GRS Certified Film, Thermoplastics, Environmentally Friendly Film, Eco-Family, BIO TPEE

ECOMATE® biofilm integrates COVATION DuPont's Susterra® biomass-derived materials into its product...

DetailsGRS CERTIFIED MEMBRANE

GRS Certified Film , Global Recycle , Environmentally Friendly Film, Eco-Family

Global Recycled Standard (GRS) is an international, voluntary, and complete product standard...

Details- Files Download

TPAE MEMBRANE - Nylon membrane, TPAE membrane | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

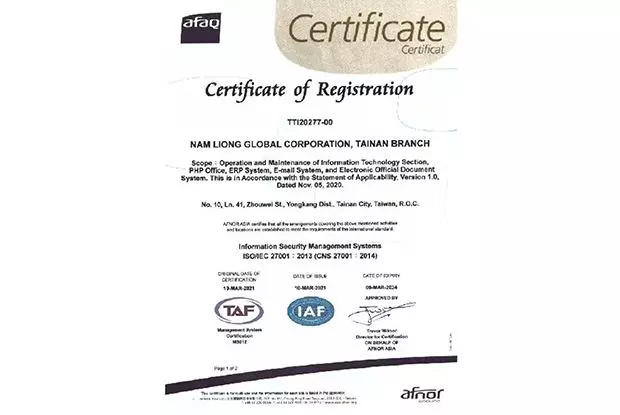

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including TPAE MEMBRANE, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.