GRS CERTIFIED MEMBRANE

GRS Certified Film , Global Recycle , Environmentally Friendly Film, Eco-Family

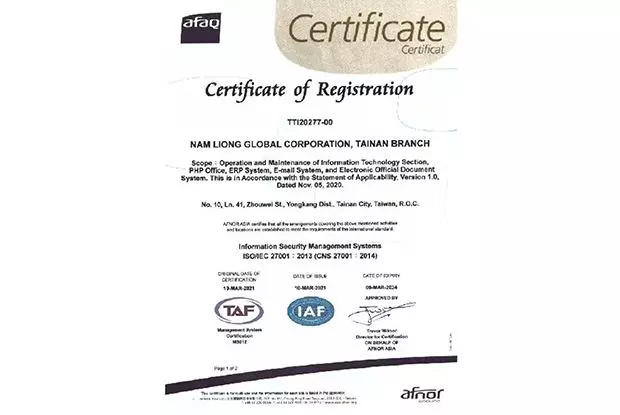

Global Recycled Standard (GRS) is an international, voluntary, and complete product standard that sets requirements for third-party certification, focusing on renewable components, social and environmental practices, and chemical use throughout the supply chain.

Global Recycled Standard (GRS) is intended to be used with any product containing at least 20% recycled materials as the goal of GRS is to increase the use of recycled materials in products and reduce / eliminate the harm caused by production during the period. After recycling,meet the gernral TPU film waterpoof requirement.

We provide TPU film and physical property testing services. You can click to view the physical properties (link in red color) of the product below, or you can make it according to your needs. Please leave a message below or call +886-6-2420633 to contact us so we can have further discussion about your needs.

Applications

- Technical Jacket, Soft Shell, Jersey, Casual Jacket, Windbreaker, Protective Clothing, Ski Suit, Shoe Pad Injection, Water Proof Shoe Lining.

Specification

- Thickness:0.02~0.1mm

- Width:100~270cm

Product Collections

GRS TPU | ||||||||

Low breathable series (Without PE carrier ) | ||||||||

Feature | ||||||||

Breathable series (With PE carrier) | ||||||||

Feature | ||||||||

Feature | ||||||||

*F:Clear/ S:Translucent/WS:White color. | ||||||||

- Related Products

BIO-BASED MEMBRANE

BioBased TPU Film, Thermoplastic Polyurethane TPU, GRS Certified Film, Thermoplastics, Environmentally Friendly Film, Eco-Family, BIO TPEE

ECOMATE® biofilm integrates COVATION DuPont's Susterra® biomass-derived materials into its product...

DetailsTPEE MEMBRANE

DetailsTPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

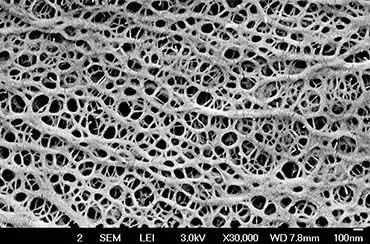

MICROPOROUS MEMBRANE

Microporous Breathable PP Film, Polyethylene

The microporous film is breathable by imitating the perspiration of the human body. There are as many...

Details- Files Download

GRS CERTIFIED MEMBRANE - GRS Certified Membrane | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

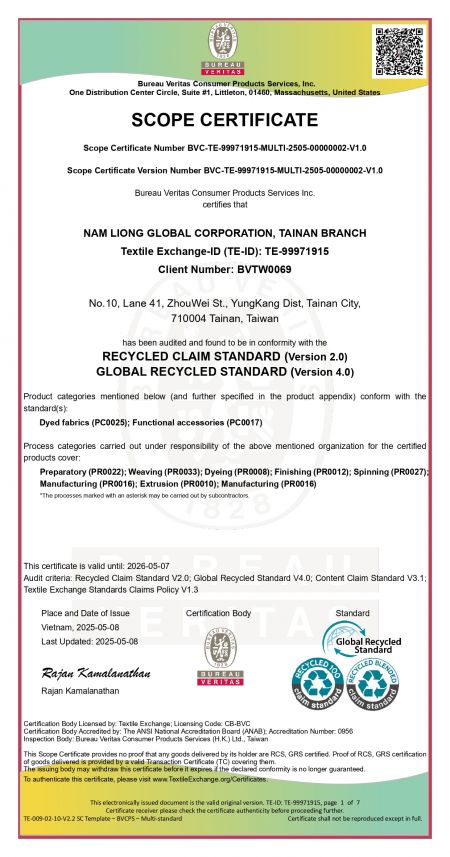

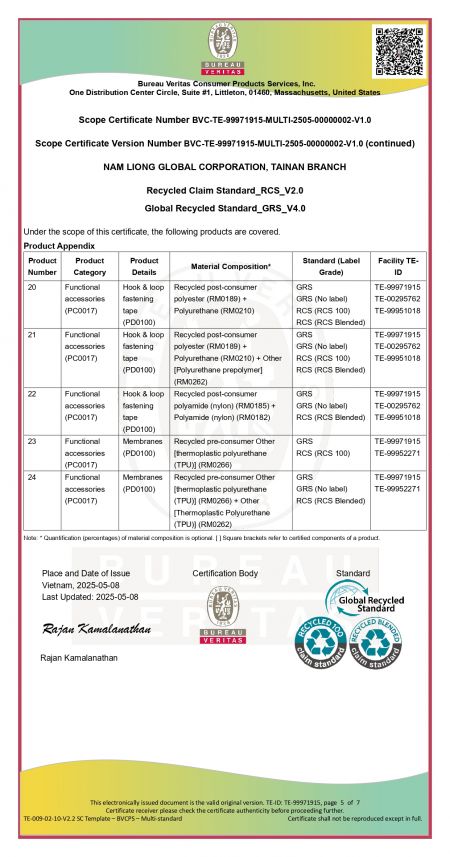

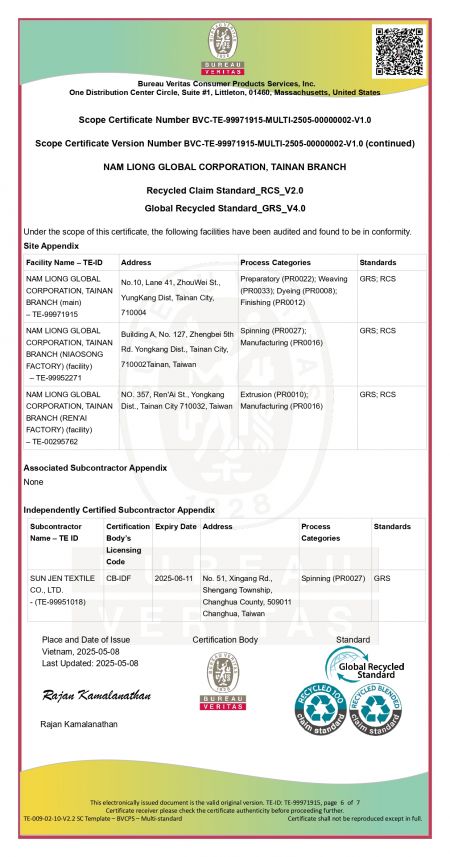

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including GRS CERTIFIED MEMBRANE, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.