Hyper Stretch Wetsuit Material

Hyper Stretch Wetsuit Material got features as soft hand feeling, high elongation rate and low modulus....

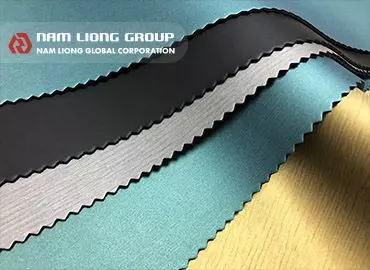

Thermal Wetsuit Material

Thermal Wetsuit Material has soft, dense, brushed surface. The loops hold in enough air to decrease...

Printed Spearfishing Wetsuit Material

Camouflage is deeply rooted in a bio-genetic function aimed at adapting to the food chain. Nam...

Super Smooth Wetsuit Material

Super Smooth Wetsuit Material is the surface treatment process on Chloroprene Rubber sponge...

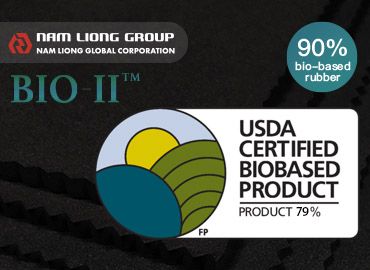

90% Bio-based Rubber Sponge

BIO-SS PLUS 90% Bio-based Rubber Sponge is the USDA (the United States Department of Agriculture)...

75% Bio-based Rubber Sponge

BIO-SS PLUS 75% Bio-based Rubber Sponge is the USDA (the United States Department of Agriculture)...

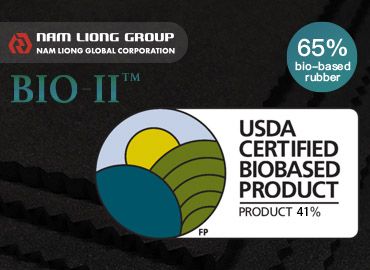

65% Bio-based Rubber Sponge

BIO-08 65% Bio-based Rubber Sponge is the USDA (the United States Department of Agriculture)...

30% Bio-based Rubber Sponge

BIO-S2H 30% Bio-based Rubber Sponge is made from renewable raw materials, such as seashell,...