Back to Back Hook and Loop

Back to Back Fastener Tape

The most original idea of back to back fastener is to have one tape with hook and loop on both faces, for self-engaging use. With one face hook the other face loop, the fastening tape can be simply operate any time and any where. Along with the technique getting well versed, new combination of back to backs are developed, such as hook on both faces, loop on both faces or one face hook or loop, the other face leather....etc.

Back to back expends more possibilities of fastening system solution from health care devises, functional garments to industrial design.

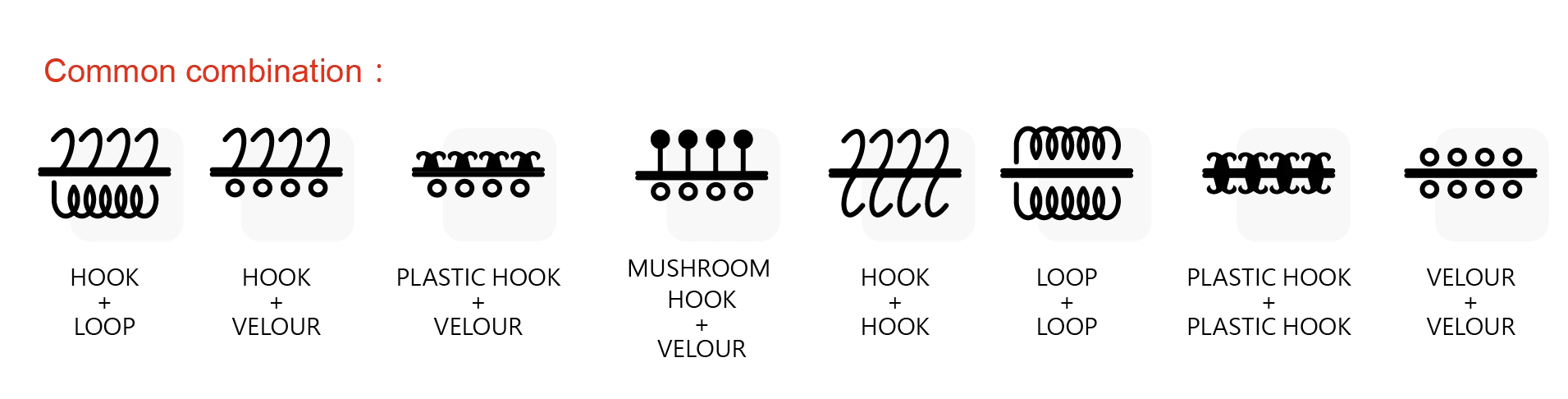

★Standard back to back combination★

Genernal hook loop on both faces

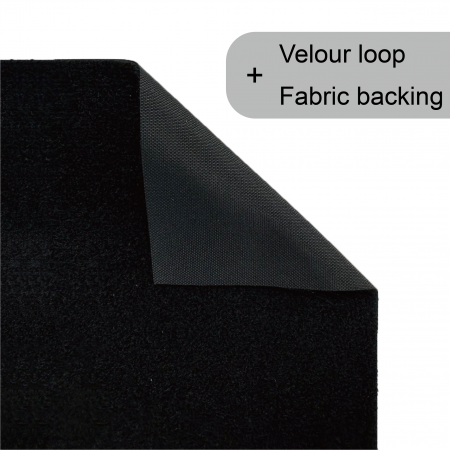

Combination can be engaged by itself : Hook + Loop b2b, Hook + Velour b2b, Mushroom hook + Velour b2b, Plastic hook + Velour b2b...etc.

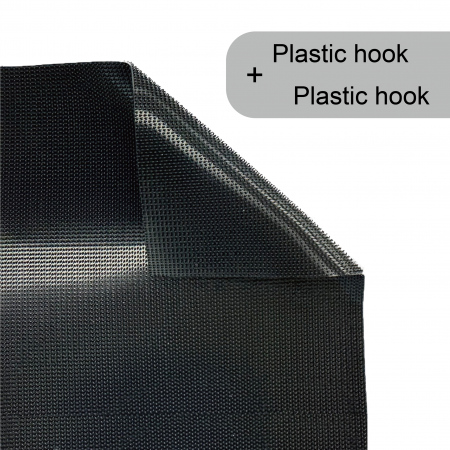

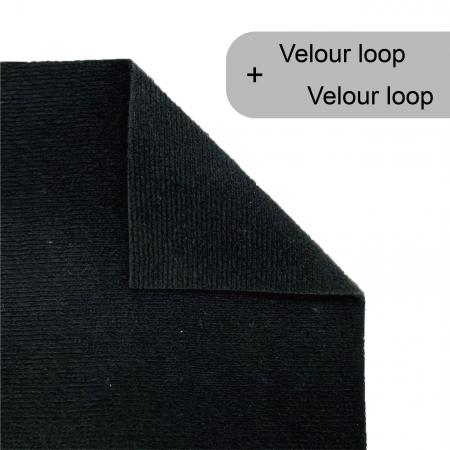

Alternative combinations : Hook + Hook b2b, Loop + Loop b2b, Velour + Velour b2b...etc.

Specification

| Standard back to back (with both faces engageable) | ||||||

|---|---|---|---|---|---|---|

| Sewon Hook | Sewon Loop | Mushroom Hook | Unnapped loop | Plastic Hook | Velour / UBL | |

| Sewon Hook | v | v | v | v | v | v |

| Sewon Loop | - | v | v | v | v | v |

| Mushroom Hook | - | - | v | v | v | v |

| Unnapped loop | - | - | - | v | v | v |

| Plastic Hook | - | - | - | - | v | v |

| Velour | - | - | - | - | - | v |

| Any type of hook and loop fastener can be back to back, please contact us for more details. | ||||||

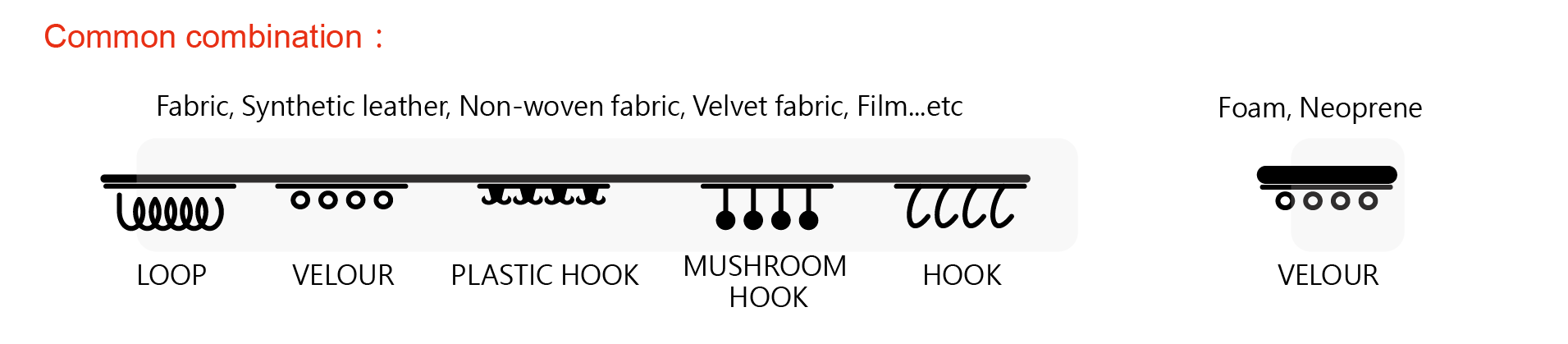

★Bespoke back to back combination★

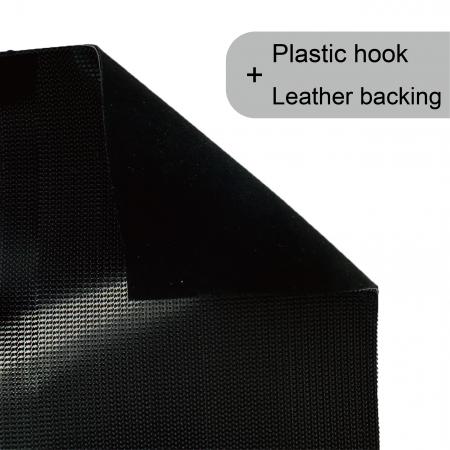

Sewon hook loop on one face, fabric/ leather or foam on the other face

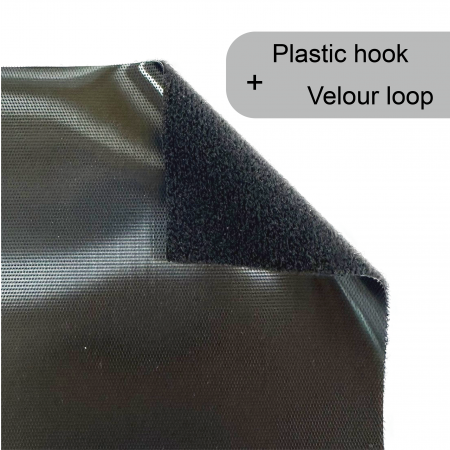

Common combinations : Hook + fabric backing, Plastic hook + leather backing, Velour + foam backing...etc.

Specification

Bespoke back to back (with one face engageable) | |||||

|---|---|---|---|---|---|

PU leather | Faux leather | Nylon fabric | Velvet | Foam | |

Sewon hook/ Loop | V | V | V | V | |

Plastic hook | V | V | V | V | |

Mushroom hook | V | V | V | V | |

Velour/ UBL | V | V | V | V | V |

We protect while we produce

In response to raising environmental awareness and engaging with ESG policies, Nam Liong upgrads lamination process from traditional solvent-based additive to solvent-free additive.

Compare to traditional solvent-based additive, solvent-free lamination produces 0 VOCs with much more stable bonding solutions at the meanwhile. With its sustainable advantage, we are able to surprise our clients with various lamination combination while move toward environmentally friendly.

Application :

●Medical industry: sphygmomanometer, wristband, medical equipment, rehabilitation products.

●Sports industry: sports equipment.

●Industrial use: work belt.

●Electronic Peripherals: Wire finishing, lining of computer bags.

●Living at home: cleaning supplies.