Industrial Rubber Sponge (CR, SBR, EPDM)

Closed-cell rubber sponge for packing, gasket and seal

Industrial-use Rubber Sponge can be used in a wide range of applications, such as gasket materials, heat preserving thermal insulation materials, special electronic components, shockproof materials, the buffer of industrial equipment, motor vehicles, and boats (gasket, seal packing collar, and cushion material).

Different polymers available for different requirements and applications, including Chloroprene Rubber (neoprene) sponge, Styrene Butadiene Rubber sponge, and Ethylene Propylene Diene Monomer (EPDM) Rubber sponge. The closed-cell structure of Industrial Rubber Sponge series has outstanding functions such as high mechanical strength, elasticity, low thermal conductivity, excellent heat retention, water proof and flame retardant.

Categorized by Polymer

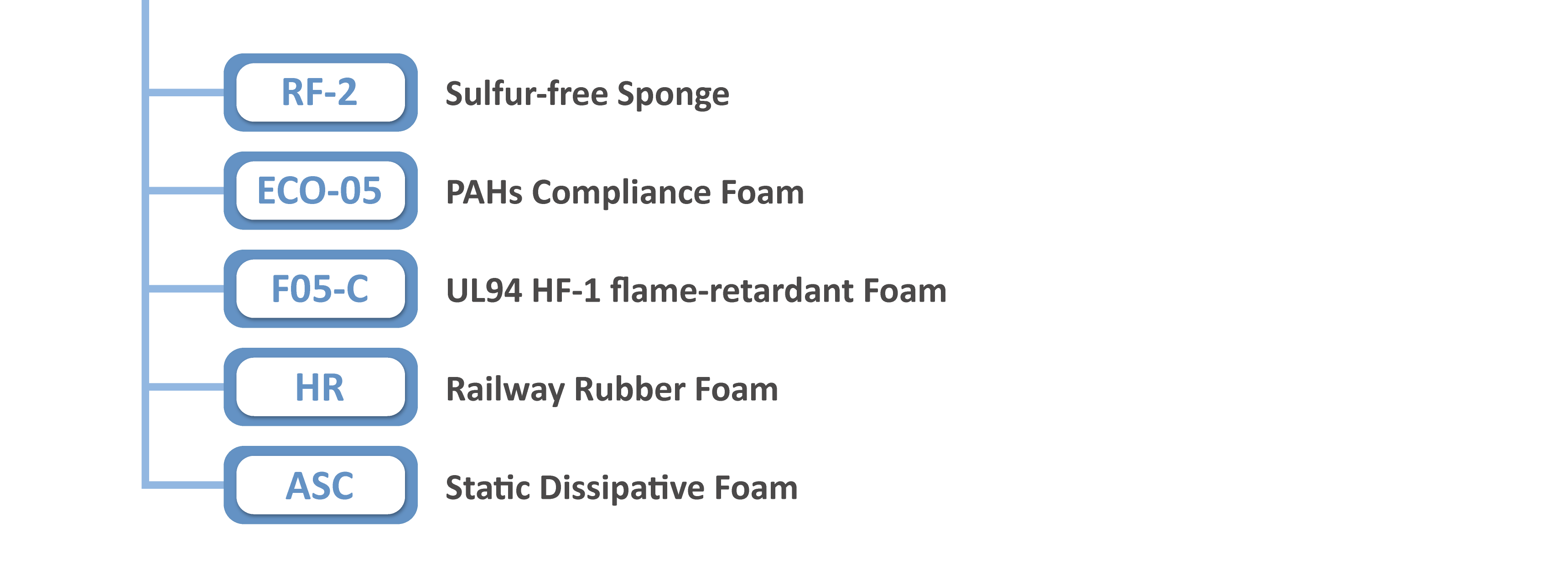

Chloroprene Rubber Foam

Chloroprene Rubber Foam is a closed-cell foaming rubber with flame retardance, chemical resistance, anti-aging, and oil resistance. Industrial CR still inherits great performances at compression set and stretch.

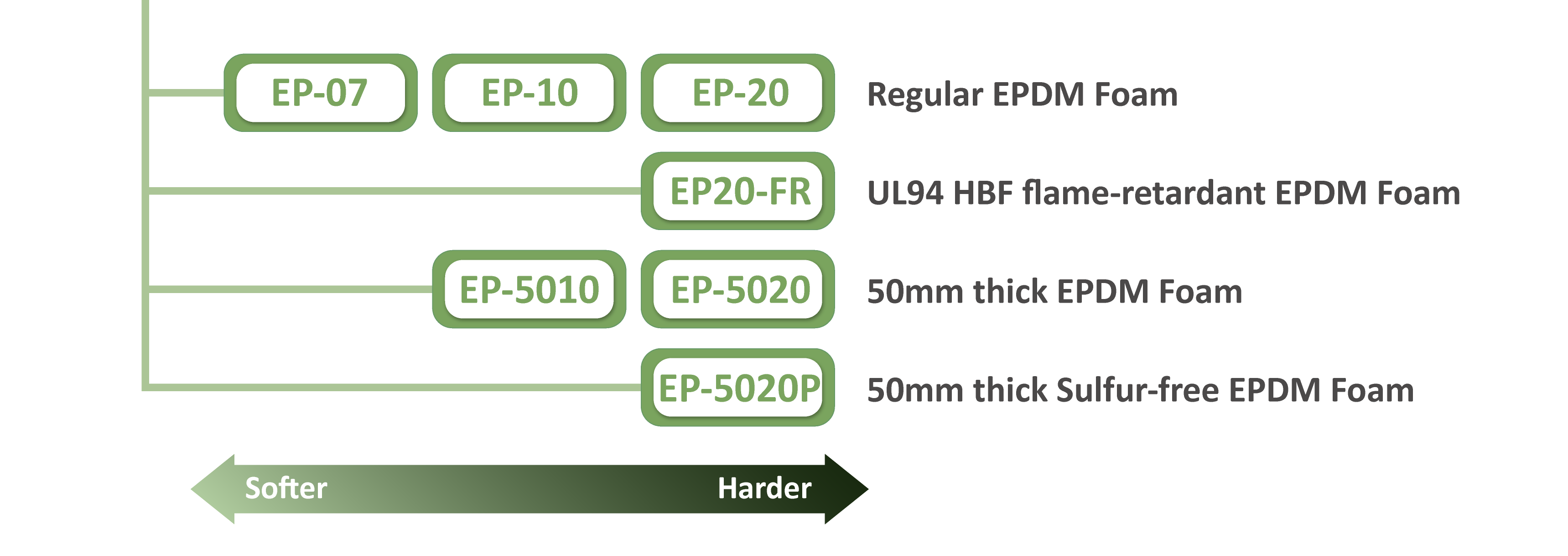

Ethylene Propylene Diene Monomer (EPDM) Rubber Foam

EPDM sponge is a halogen-free and closed-cell foaming rubber known for its excellent weather resistance, ozone resistance, acid and alkali resistance, and heat resistance. It is particularly suitable for applications that require prolonged exposure to outdoor environments, such as automotive and marine cushioning materials, seals, and gaskets. Most EPDM sponges comply with the FMVSS 302 standard, which tests the flammability and flame resistance of materials used in vehicle interiors.

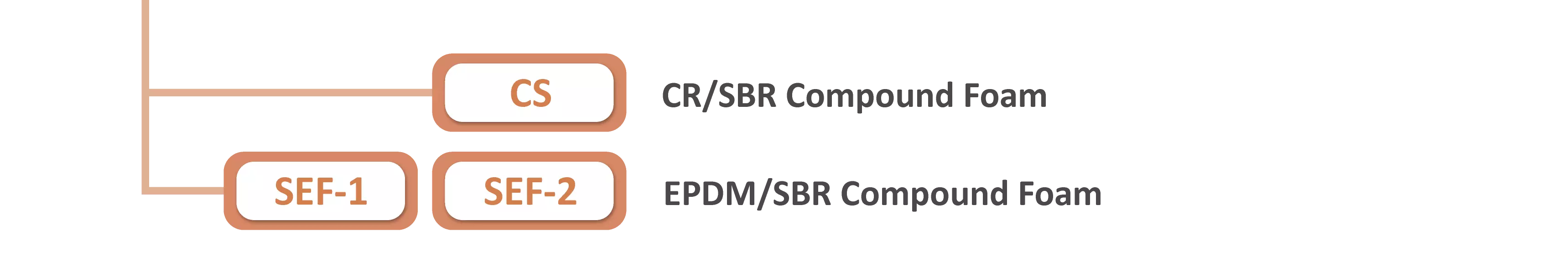

Styrene Butadiene Rubber (SBR) Foam

SBR can be blended with CR or EPDM to enhance cost-efficiency. The raw materials for SBR are more readily accessible than those of other rubbers, and incorporating SBR into the polymer blend improves processability.

Product Collections

| Polymer | Model | ASTM D1056-00 | Hardness (Asker Type C) | Remarks |

|---|---|---|---|---|

| CR | RF-2 | 2C1 | 7 ± 3 | UL94 HF-1 Pass & FMVSS 302 Pass |

| ECO-05 | 2C3 | 21 ± 5 | UL94 HF-1 Pass & FMVSS 302 Pass & PAHs Pass | |

| F05-C | 2C3 | 25 ± 5 | UL94 HF-1 Certificate FMVSS 302 Pass DIN 5510-2 (S3, SR2, St2) | |

| HR | 2C2 | 20 ± 5 | High L.O.I. BSS7239 Pass ASTM E3675 Is < 25 ASTM E662 Ds max. 300 | |

| ASC | 2C1 / 2C2 | 9 ± 3 | UL94 HBF Pass Static Dissipative: 107 ~ 1010 Ω | |

| CR/SBR | CS | 2C2 | 23 ± 5 | |

| SBR/EPDM | SEF-1 | 2A1 | 7 ± 3 | |

| SEF-2 | 2A1 / 2A2 | 10 ± 3 | ||

| EPDM | EP-07 | 2A1 | 7 ± 5 | FMVSS 302 Pass |

| EP-10 | 2A1 / 2A2 | 10 ± 5 | FMVSS 302 Pass | |

| EP-20 | 2A2 | 20 ± 5 | FMVSS 302 Pass | |

| EP-20FR | 2A2 | 20 ± 5 | UL94 HBF Pass | |

| EP-5010 | 2A1 / 2A2 | 10 ± 5 | Thickness 50mm FMVSS 302 Pass | |

| EP-5020 | 2A2 | 20 ± 5 | Thickness 50mm FMVSS 302 Pass | |

| EP-5020P | 2A2 | 22 ± 4 | Thickness 50mm FMVSS 302 Pass Sulfur-free |

Applications

Gasket, heat preserving thermal insulation, electronic components, shockproof materials, buffer material in the machine, vehicle and boat.

Nam Liong Story

A Sustainable Textile Industry For A Brighter Future - ESG Report

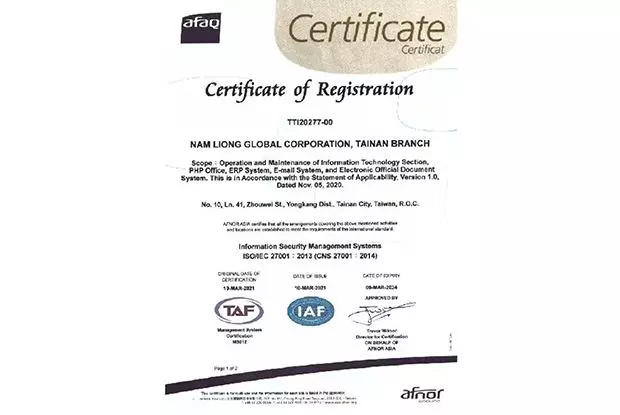

Circular Economy is a systems solution framework that tackles global challenges. As a textile manufacturer, Nam Liong has been implementing ISO systems and meeting international standards to protect our planet. In 2022, An ESG report with the certification of AA1000 SES was delivered as a communication tool between Nam Liong and stakeholders.

Sulfur-free Rubber Foam

RF-2

Sulfur-free Rubber Foam has the characteristics of flame-retardant, oil-resistance, chemical-resistance,...

DetailsPAHs Compliance Rubber Foam

ECO-05 / Eco-Family

Polycyclic Aromatic Hydrocarbons (PAHs) compliance Chloroprene rubber foam with the closed-cell...

DetailsUL94 HF-1 flame-retardant Rubber foam

F05-C

UL94 HF-1 Flame-retardant Rubber Foam is the closed-cell rubber foam with excellent characteristics...

DetailsRailway Rubber Foam

HR

Railway Rubber Foam is developed for railway industry. Apart from having the excellent characteristics...

DetailsStatic Dissipative Rubber Foam

ASC

Static Dissipative Foam is made of Chloroprene Rubber (neoprene) with closed-cell structure....

DetailsHigh Hardness Rubber Foam

CS

High Hardness Foam is made of compounded rubber that has both the good physical characteristic...

DetailsRegular EPDM Foam

EP-07, EP-10, EP-20

Ethylene Propylene Diene Monomer (EPDM) Rubber Foam with the closed-cell structure resists...

DetailsUL94 HBF flame-retardant EPDM Foam

EP-20FR

UL94 HBF flame-retardant EPDM Foam with the closed-cell structure resists to weather, ozone,...

Details50mm thick EPDM Foam

EP-5010, EP-5020

50mm thick EPDM Foam are the closed-cell foam with excellent resistance to weather, ozone,...

Details50mm thick Sulfur-free EPDM Foam

EP-5020P

50mm thick Sulfur-free EPDM Foam is similar to 50mm thick EPDM Foam with excellent resistance...

DetailsEPDM/SBR Compound Foam

SEF-1, SEF-2

EPDM/SBR compound foam is the composite of Ethylene Propylene Diene Monomer (EPDM) and Styrene-Butadiene...

DetailsIndustrial Rubber Sponge (CR, SBR, EPDM) - Closed-cell rubber sponge for packing, gasket and seal | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Industrial Rubber Sponge (CR, SBR, EPDM), Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.