Film / Membrane

High Performance Polymer Film、Thermoplastics

Outdoor and leisure activities bring people closer to nature and create a variety of product business opportunities with different functions to meet the needs of consumers. However, behind the large amount of consumption, it also means environmental costs incurred before and after consumption. The uneven quality of products may lead to local health risks.

In the spirit of corporate social responsibility, Nam Liong focuses on green environmental protection in product development. From manufacturing to service, from material selection to production process, Nam Liong is committed to eco-friendly and harmlessness, and optimizes the use of resources and recycling. Moving forward with the ESG goals of carbon reduction and sustainability.

TPU film is different from PVC in that no plasticizer is used in the production process and most of it can be recycled and reused; TPEE film laminated with Poly fabric as mono-material can be recycled and reused; PTFE microporous film is made of polytetrafluoroethylene. It is made of materials with excellent functions, however, there is a lot of controversy over its environmental hazards in production and use. Therefore, Nam Liong launchs an eco-friendly microporous membrane made of PP to meet the environmental protection trend and be fluorine-free, realizing the contribution to sustainability.

Nam Liong has been investing in the field of waterproof and breathable membrane materials for over 50 years. Our products are all developed and made in Taiwan. TPU film enables eco-friendly manufacturing processes and products. TPEE film can provide recycling and reuse solutions for the industry to achieve a circular economy. PP microporous film is the best green material choice to replace PTFE.

2016 Become bluesign® system partner(Nanxiong Jiaxing China)

2018 Bluesign® approved (Nanxiong Jiaxing China)

2019 Pass Oeko-Tex Class I (TP001 159432)

2020 Pass Global Recycled Standard (GRS) certificate

2022 Ecomate® DPA1SE 27% BIO content by BETA Lab with USDA certification

2023 TPU membrane TS102A phenolic yellowing resistance up to 4.0 grade(ASTM G155-21)

2023 Become bluesign® system partner (Namliong Taiwan)

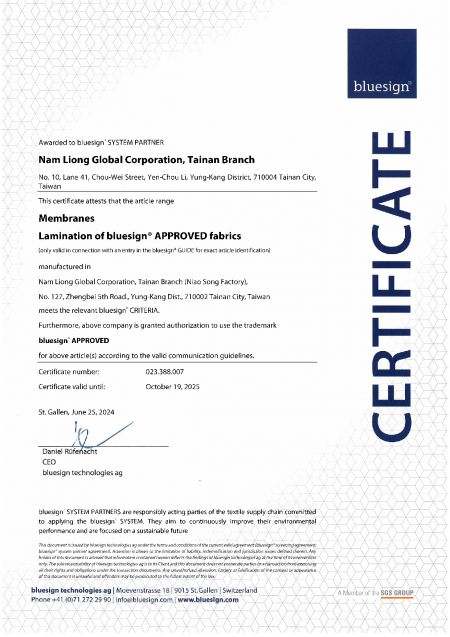

2024 Bluesign® approved (Namliong Taiwan)

2024 HIGG completion (Namliong Taiwan)

Please continue to go to Check the introduction of film materials below, there are more detailed content to help you find suitable film materials.

Hydrophilic membrane UREAMAX® | |||

Processed material | Features | Environmental advantages | Applications |

TPU | Waterproof, moisture-permeable, hydrolysis-resistant, chemical-resistant, tear-resistant, soft hand feel, flexibility | Plasticizers.& solvents free | ‧Garment ( Soft shell, Hard shell, Raincoat, wind break, Down Jacket, Motorcycle Wear, Hunting Wear, Workwear, Horse Clothes, etc.) |

TPEE | The waterproof and breathable performance is not inferior to that of TPU film | Recyclable mono-material concept | ‧Garment ( Soft shell, Hard shell, Raincoat, wind break, Down Jacket, Motorcycle Wear, Hunting Wear, Workwear, Horse Clothes, etc.) |

TPAE | Recyclable mono-material concept | Garment ( Soft shell, Hard shell, Raincoat, wind break, Down Jacket, Motorcycle Wear, Hunting Wear, Workwear, Horse Clothes, etc.) | |

PU | waterproof and good moisture-permeable, soft hand feel, flexibility, high temperature resistance | Bio-base PU membrane | Garment ( Soft shell, Hard shell, Raincoat, wind break, Down Jacket, Motorcycle Wear, Hunting Wear, Workwear etc.) |

MICROPOROUS MEMBRANE | |||

Processed material | Features | Environmental advantages | Applications |

PP | thermoplastic polyester elastomer | The process is more energy-saving and fluorine-free | Waterproof and breathable, good water resistance. Moisture permeability is not affected by the climate, and the effect is even better! |

Applications

- Garment, home textile fabrics, film for functional shoes, waterproof products, functional jackets, tents and other outdoor products.

High-heat-resistant TPU membrane

Heat-resistant low-transmittance TPU film, heat-resistant TPU film

TPU film is a critical material for airtightness, durability, and comfort in the production...

DetailsTPAE MEMBRANE

Thermoplastic Polyamide Elastomer Film

The TPAE film Namliong developed can be laminated with Nylon fabric to form a mono-material...

DetailsTPU MEMBRANE

Thermoplastic Polyurethane Resin, Waterproof And Moisture-Permeable Film, Eco-Family

UREAMAX® TPU film is made of thermoplastic polyurethane, an environmentally friendly material,...

DetailsTPEE MEMBRANE

TPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

MICROPOROUS MEMBRANE

Microporous Breathable PP Film, Polyethylene

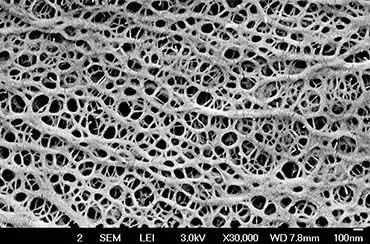

The microporous film is breathable by imitating the perspiration of the human body. There are as many...

DetailsAliphatic TPU

Anti-yellowing TPU, TPU 2.0, Aliphatic

Aliphatic TPU film is different from general aromatic TPU, which has excellent resistance to UV radiation...

DetailsFilm / Membrane - High Performance Polymer Film、Thermoplastics | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

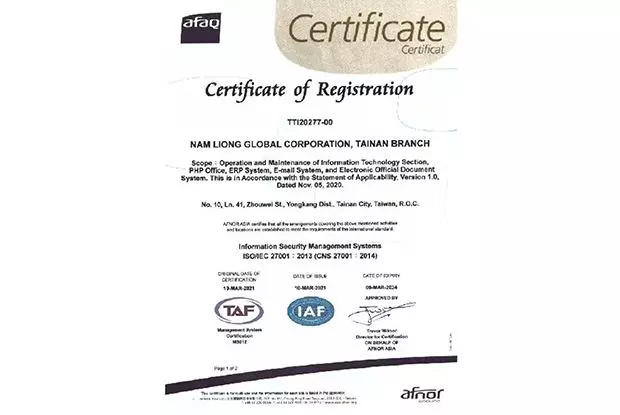

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Film / Membrane, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.

.jpg?v=73a2f126)

.jpg?v=41267b46)