Quality Assurance

Quality Policy

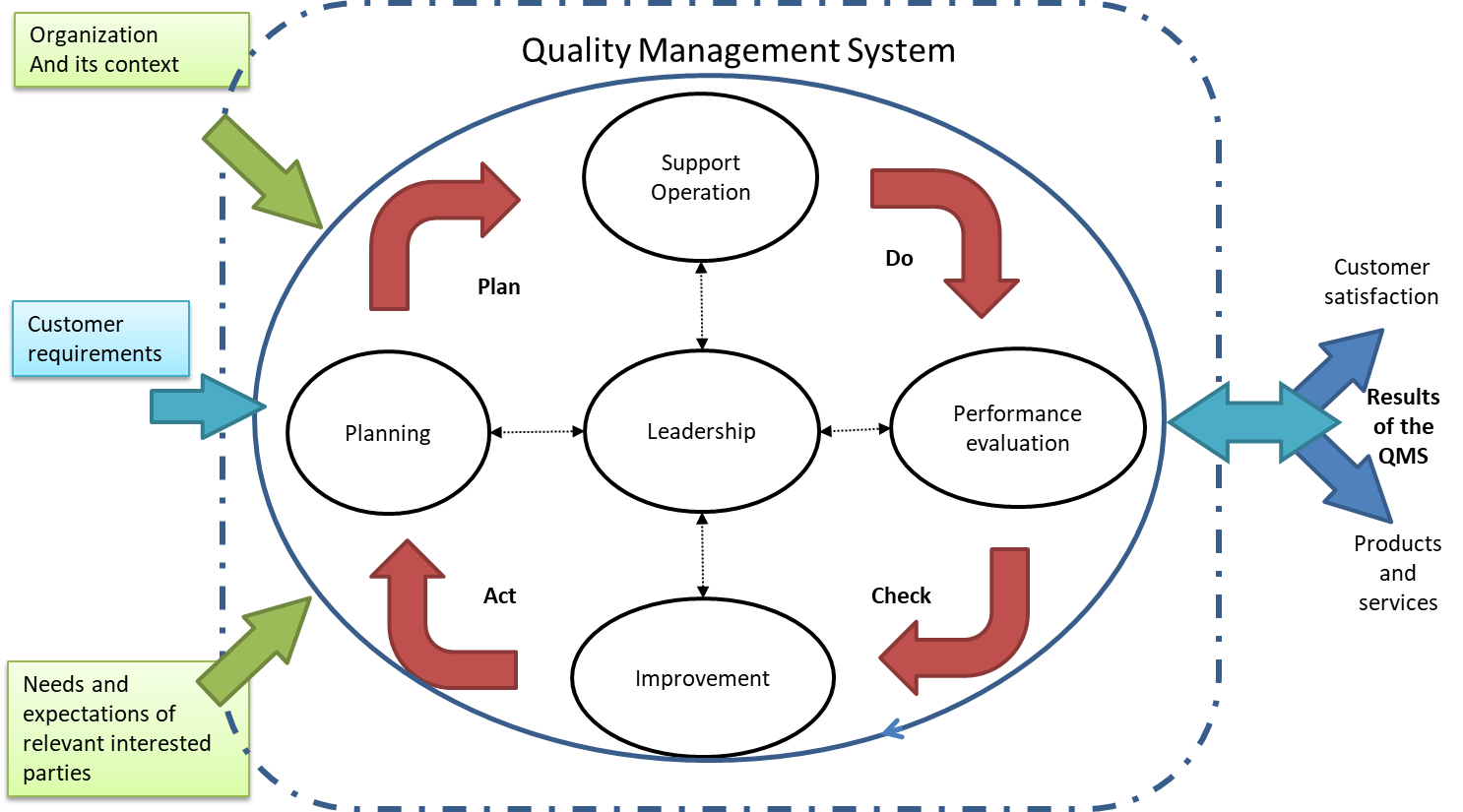

Nam Liong Global quality management system is constantly being improved through continuous PDCA cycle to ensure the effectiveness, adequacy, and applicability.

-Stable quality

-Accurate delivery

-Fair price

-Customer satisfaction

-Continuous improvement

Quality System Architecture Diagram

Organizational Structure and Tasks of Quality Assurance Department

The Quality Assurance Department manages three units : "Quality Control Section", "Testing and Verification Section" and "System Management Section", plays the role of the headquarter and manages three oversea units including "Liaobu Quality Assurance Center", "Jiaxing Quality Assurance Center" and "Vietnam Quality Assurance Center" in a horizontal matrix. The organizational tasks are as follows : (1) Continuous improvement promotion of quality operation process, standardized operational procedure planning, execution, inspection, and improvement. (2) Physical quality control operations for incoming materials, manufacturing processes and finished products. (3) Calibration of all gauges and instruments. (4) Quality assurance laboratory management, including maintenance, calibration and operational arrangements of various inspection equipment. (5) Planning, implementation and supervision of the company's various systems and product certification operations. (6) Issuance control operation of the company's domestic and oversea regulation documents. (7) Analysis, tracking and verification of major quality events. (8) Promote 6S environmental management activities and pursue a working environment for sustainable enterprise management. (9) Promote the improvement proposal system, and encourage employees to actively propose various improvement cases.

Certification

Quality assurance laboratory

Taiwan Quality Assurance Department plays the role of the headquarters and manages the four domestic and oversea laboratories. They are Taiwan Quality Assurance Laboratory, Liaobu Quality Assurance Laboratory, Jiaxing Quality Assurance Laboratory and Vietnam Quality Assurance Laboratory. Each laboratory is equipped with professional testing equipment related to rubber, plastic polymers or textile materials.

Professional testing equipment

| Device | Description |

|---|---|

| Table type computer tensile compress tester | Various built-in experiments, calculation formulas and statistical analysis, such as tensile test, peeling test, tearing analysis, strength, bending, fatigue, etc. Compliant with many international test regulations. |

| Temperature & Humidity Tester | Programmable control environment temperature -40 ~ 100°C, and humidity 30 ~ 95% of the testing environment, for the breathability test and environmental test of the product. |

| abrasion tester | Compliant with ASTM D3886, ASTM D3884 and ISO-12947 testing regulations, providing abrasion test for shoe materials, bag materials, garments and industrial fabrics. |

| as pilling tester | Compliant with ASTM D3512 testing specifications, providing pilling test for cloth. |

| hydrostatic pressure tester | Compliant with AATCC 127 testing specifications, providing hydrostatic pressure testing for film lamination products. |

| Washing machine Tumble dryer | Compliant with AATCC 135 machine wash specifications. |

| Normal temperature holding power tester | Compliant with PSTC testing specifications, providing adhesive strength testing for rubber products. |

| Oven type holding power tester | Compliant with PSTC testing specifications, providing adhesive strength testing for rubber products. |

| Cutting machine | Compliant with ISO-13997 (1999 edition), latest cutting resistance test for protective equipment products. |

| Specific gravity balance | Compliant with ASTM, using Archimedes' water displacement method to test the specific gravity of substances. |

| Flame Tester | Compliant with FAR 25.853, UL-94, FMVSS 302, ISO and other fire resistance tests. |

| Viscometer | Compliant with ASTM adhesive viscosity test. |

| Melt flow indexer | Compliant with thermoplastic melt quality and melt volume flow rate of ISO, ASTM. |

| Moisture Tester | Based on the principle of thermogravimetry, the sample is rapidly heated to evaporate the water, to determine the moisture content of the substances. |

| Color fastness testing machine | Compliant with various color fastness testing regulations, providing color fastness test for products. |