Closed-cell Rubber Sponge (CR, SBR)

Closed-cell chloroprene rubber sponge, Styrene butadiene rubber sponge

The closed-cell structure of Nam Liong SEAMATE® Chloroprene rubber sponge (neoprene) is with a series of outstanding performance characteristics:

• Soft and Comfortable: Excellent elasticity and softness, providing the best wearing experience.

• Waterproof Protection: Effectively waterproof, ensuring dryness and comfort.

• Cushioning and High Strength: Provides protection and enhances impact resistance.

• Cold Resistance and Insulation: Exceptional thermal insulation properties, suitable for low-temperature environments.

• Sea Water Resistance and Flame Retardancy: Resistant to sea water corrosion and has flame retardant properties.

• Ozone Resistance: Can withstand ozone damage for extended periods.

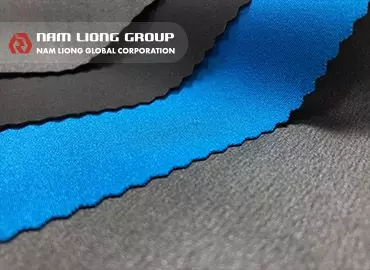

Additionally, SEAMATE® Neoprene / Chloroprene Rubber can be combined with various fabrics, customized according to different needs, and is widely used in products such as wetsuits, surf suits, protective gear, bags, shoes, and more.

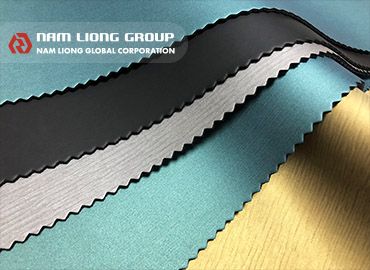

To meet diverse customer requirements, Chloroprene Rubber can also be blended with Styrene-Butadiene Rubber, combining the properties of both materials.

*For more detailed information about the main rubber, please click the link below.

got the features as soft, waterproof, good hermetic seal, adhesion force, heat preservation and high strength, resistance to seawater, chemicals and fire.

Chloroprene rubber sponge laminated with various fabrics are suitable materials for diving suit, surfing suit, water sports suit, speafishing suit, immersion suit, survival suit, life vest, computer bag, sport use and medical protection equipment and so on.

Chloroprene rubber / Styrene butadiene rubber compound sponge (CR / SBR) contains the characteristics of both polymers. Various foams with different percentage of Chloroprene rubber are produced to meet different requirements.

Chloroprene Rubber Sponge (CR Sponge)

The structure of the chloroprene rubber sponge is the foamed rubber sponge with closed cell structures with good elasticity. It has the features of soft hand-feeling, water-proof, weather-resistance and warm-keeping and resistance to sea water, chemicals, fire and ozone.

Styrene Butadiene Rubber Sponge (SBR Sponge)

Styrene Butadiene Rubber Sponge (SBR Sponge) is the closed-cell foam with the characteristics of low water-absorption, warm-keeping and buffer. Most of the foams in this series are compounded with Chloroprene Rubber for better physical performances and have the advantages of both polymers.

Eco-friendly Rubber Sponge Laminate

Chloroprene Rubber sponge (CR Sponge) and Styrene Butadiene Rubber Sponge (SBR Sponge) with low toxicity, Oeko-Tex standard 100 Certificated Rubber Foam Laminate has got Oeko-Tex Standard 100 certification, also fulfill the international standards such as REACH/SVHC, RoHS, CPSIA, PAHs and PVC-Free.

Bio-based rubber sponge (BIO-II)

Bio-based rubber sponge is 100% neoprene free, no Chlorine content. The first rubber sponge which have USDA Bio-based product approval, also fulfill the international standards. Natural rubber tree, seashells and non-edible plant oil are used to replace some of the raw materials for reducing the mining of mineral resources and pollution.

Applications

- Wetsuit, drysuit, swimsuit, neoprene fitness suit, knee support, sports sleeve, shoes, bags and so on.

Gallery

- https://technical-fabric.namliong.com.tw/en/page/Water-Repellency-Technique-on-Neoprene-Sheet-for-Your-Luxury-Bag-Market/neoprene-sponge.html

Nam Liong Story

Water Repellency Technique On Neoprene Sheet For Your Luxury Bag Market

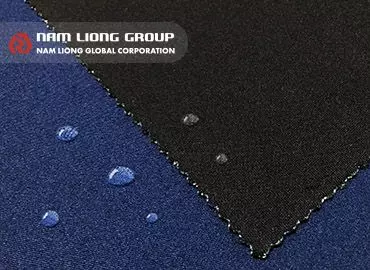

Nam Liong has developed a water repellency technique to address the contradiction between having a neoprene fabric that is water repellent and has great adhesive bonding. After water repellency technique is applied, AATCC22 water repellency spray test shows that neoprene fabric remains 70% waterproof.

Chloroprene Rubber Foam

CR Sponge

High-Performance:Solutions to Enhancement SpecialityAre you struggling with these challenges?...

DetailsStyrene butadiene rubber (SBR) Sponge

CR/SBR Sponge

SBR as Alternative to Cost Control: Are you facing these challenges? Rising material costs,...

DetailsXperience™ Thin High-Performance CR Sponge Bun

3DX-5, QF, QFP, QFL

Conventional chloroprene rubber sponge buns, typically produced at 25~35mm thick, offer limited...

DetailsOeko-Tex standard 100 Certificated Rubber Foam Laminate

ECO-Sponge / Eco-Family

OEKO-TEX® Standard 100 Certified Rubber Sponge LaminateEco-Friendly Innovation for High-Performance...

DetailsHyper Stretch Wetsuit Material

QT, SF, NL555, AQ2, 2N…

Hyper Stretch Wetsuit Material got features as soft hand feeling, high elongation rate and low modulus....

DetailsThermal Wetsuit Material

PP, Thermal, QDS…

Thermal Wetsuit Material has soft, dense, brushed surface. The loops hold in enough air to decrease...

DetailsPrinted Spearfishing Wetsuit Material

DPNL, PPN, PPL

Camouflage is deeply rooted in a bio-genetic function aimed at adapting to the food chain.Nam...

DetailsSuper Thin Rubber Foam Laminate

ZERO X, ZERO 3, ZERO 5

Super Thin Rubber Foam (neoprene) Laminate is the material with multi-layer and multi-function....

DetailsSuper Smooth Wetsuit Material

Neoskin, Slickskin, Slipskin, ORCA, ENSS…

Super Smooth Wetsuit Material is the surface treatment process on Chloroprene Rubber sponge...

DetailsWetsuit Tape

Neoskin tape

Wetsuit tape is the seam sealing tape on the inside layer of a wetsuit to provide high smoothness,...

DetailsWater-Repellent Treatment

Aqua-Blocking (AB) Treatment

For the regular water-repellent treated lamination in the market, the fabric would be peeled...

DetailsEmbossed Rubber Foam

Skin Embossed, Fabric Embossed, Cell Embossed

Rubber foam can be embossed to enhance the surface strength and the performance of anti-slip....

DetailsClosed-cell Rubber Sponge (CR, SBR) - Closed-cell chloroprene rubber sponge, Styrene butadiene rubber sponge | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

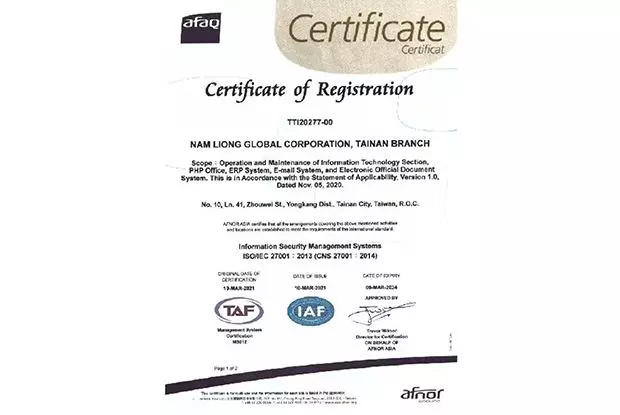

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Closed-cell Rubber Sponge (CR, SBR), Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.