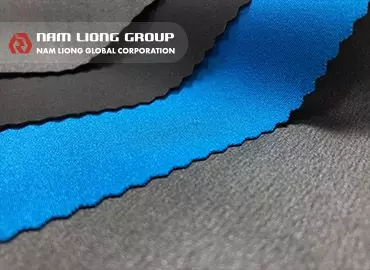

Xperience™ Thin High-Performance CR Sponge Bun

3DX-5, QF, QFP, QFL

Xperience™ Neoprene Thin Foam Block

Conventional chloroprene rubber sponge buns, typically produced at 25~35mm thick, offer limited usable smooth skin surface. With thickness options ranging from 10 to 16mm, Xperience™ Thin High-Performance CR Sponge Bun delivers greater skin utilization and allow direct use or splitting to meet specific product requirements.

Xperience™ provides excellent compression recovery and dependable low-temperature performance—making it an ideal material choice for diving, spearfishing, and competitive water sports.

More efficient thickness, greater freedom in design.

Features

- Made with limestone-based Chloroprene Rubber.

- Available thickness options: 10 / 13 / 16mm.

- Ultra-soft hand feel (Asker Type C hardness below 2).

- Low modulus for easy stretching and high elongation.

- Scratch-resistance skin surface.

- Suitable for embossing and camouflage surface processing.

Product Collections

| Properties | Test Method | 3DX-5 | QF | QFP | QFL |

|---|---|---|---|---|---|

| Elongation (%) | ASTM D412 | 650↑ | 600↑ | 450↑ | 500↑ |

| Tensile (kg/cm²) | ASTM D412 | 6.0↑ | 5.0↑ | 5.5↑ | 5.0↑ |

| Hardness (Asker type C) | ASTM D2240 | 2.0↓ | 2.0↓ | 3.0↓ | 2.0↓ |

| Density (g/cm³) | ASTM D1817 | 0.18±0.02 | 0.19±0.02 | 0.20±0.02 | 0.14±0.02 |

| Modulus at 200% (kg/cm²) | ASTM D412 | 0.5~1.2 | 0.6~1.6 | 1.0~3.0 | 0.8~2.2 |

| Compression set (50% 22hrs 25°C) | ASTM D395 | 10↓ | 20↓ | 20↓ | 15↓ |

| Thickness (mm) | - | 10 / 13 / 16 | 13 / 16 | 13 / 16 | 10 / 13 / 16 |

| Remarks | - | Best strength and highest elongation | Best cost-efficiency | — | Highest buoyancy and lightest weight |

Minimum Order

100 buns

Applications

- Spearfishing, triathlon, and freediving wetsuits, as well as other applications requiring smooth-skin CR sponge processing.

Nam Liong Story

Water Repellency Technique On Neoprene Sheet For Your Luxury Bag Market

Nam Liong has developed a water repellency technique to address the contradiction between having a neoprene fabric that is water repellent and has great adhesive bonding. After water repellency technique is applied, AATCC22 water repellency spray test shows that neoprene fabric remains 70% waterproof.

- Related Products

Chloroprene Rubber Foam

CR Sponge

High-Performance:Solutions to Enhancement SpecialityAre you struggling with these challenges?...

DetailsSuper Thin Rubber Foam Laminate

ZERO X, ZERO 3, ZERO 5

Super Thin Rubber Foam (neoprene) Laminate is the material with multi-layer and multi-function....

Details

Xperience™ Thin High-Performance CR Sponge Bun - Xperience™ Neoprene Thin Foam Block | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

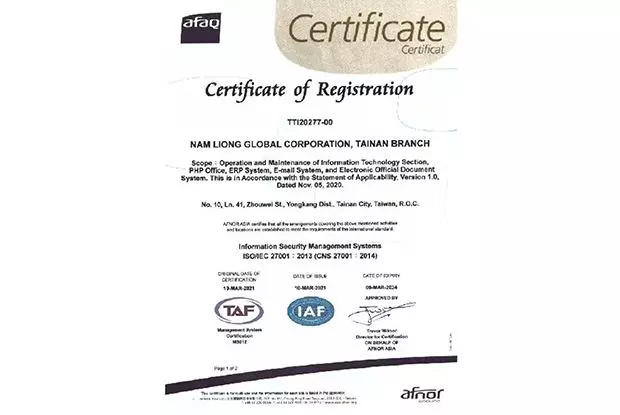

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Xperience™ Thin High-Performance CR Sponge Bun, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.