Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

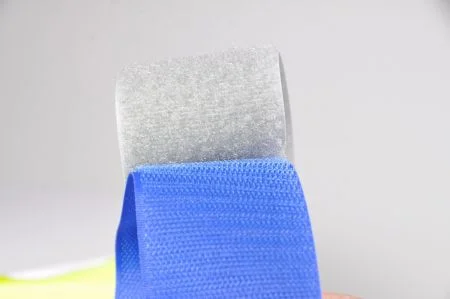

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.

View our quality products

Wetsuit Material,

Rubber Sponge,

TPU Membrane,

Fastening Tape,

Resistant Fabric,

Knitted Fabric,

Anti-Slip Fabric,

Puncture Resistant Fabric,

Stretch Fabric,

Reflective Fabrics,

Fire Retardant Fabric,

Multifunctional Fabrics and feel free to

Contact Us.