Polymeric foam

Closed-cell sponge

Rubber Sponge Division of Nam Liong Global Corporation is professional on developing and manufacturing the closed-cell foams with many kinds of polymers, such as Natural Rubber, Chloroprene Rubber (so-called neoprene), Styrene butadiene rubber (SBR), Thermoplastic Elastomer (TPE), Ethylene Vinyl Acetate (EVA), Ethylene Propylene Diene Monomer Rubber sponge (EPDM) and so on.

We are committed to using the natural, renewable or recycled raw materials to replace some of the petrochemical contents as much as possible for lowering the environment impact to the earth. Our products are approved by Oeko Tex Standard 100, USDA BioPreferred program, Global Recycle Standard (GRS), etc.

The closed-cell foams have the good performance of warm-keeping, water-proof and cushion. The sliced foam can be laminated with various fabrics for the consumer finished products or can be die cut for the industrial use. The production facilities are located in Taiwan, China and Vietnam.

Brand logos

SEAMATE®

Rubber sponge laminates for consumer products, such as wetsuit, gloves, shoes, bags and so on.

ECoreBond™

Light-weight eco-friendly thermoplastic sponge laminates and bio-based thermoplastic foam.

Applications

- Consumer-use applications : Wetsuit, drysuit, swimwear, neoprene fitness suit, medical supports, sports supports, shoes, bags and so on.

- Industrial-use applications : Gasket or seal for heat insulation, shock-absorption in machine, automobile or ship.

Nam Liong Story

Water Repellency Technique On Neoprene Sheet For Your Luxury Bag Market

Nam Liong has developed a water repellency technique to address the contradiction between having a neoprene fabric that is water repellent and has great adhesive bonding. After water repellency technique is applied, AATCC22 water repellency spray test shows that neoprene fabric remains 70% waterproof.

Closed-cell Rubber Sponge (CR, SBR)

The closed-cell structure of Nam Liong SEAMATE® Chloroprene rubber sponge (neoprene) is with...

Thermoplastic Sponge Materials

Various foam materials with the polymers of Ethylene-Vinyl Acetate (EVA), Polyethylene (PE),...

Bio-based Sponge

Nam Liong Global Corporation is committed to developing eco-friendly products. In order to reduce...

Industrial Rubber Sponge (CR, SBR, EPDM)

Industrial-use Rubber Sponge can be used in a wide range of applications, such as gasket materials,...

Recycled Rubber Sponge

【Are you one of the following customers?】 ★ Businesses in textiles, flooring, construction,...

Eco-Friendly Textile — Dope-dyed and Recycled Fabric

Are you looking for the recycled neoprene? The recycled fabric laminated with the rubber sponge...

Polymeric foam - Closed-cell sponge | Over 50 Years High-Performance Technical Fabric and Bio Rubber Sponge Manufacturer | Nam Liong

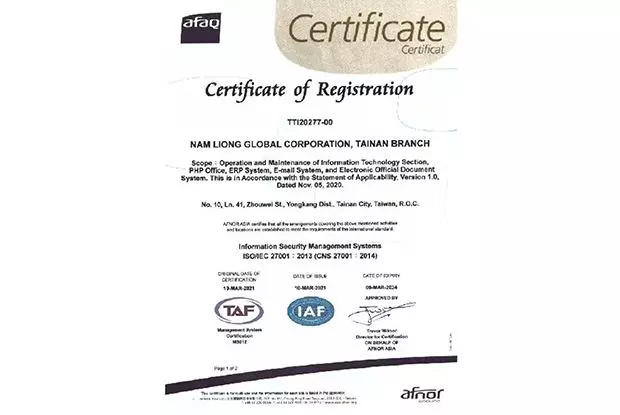

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Polymeric foam, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.

-1.png?v=7a2793f2)

.jpg?v=80af0cd0)