MEDICAL INFLATABLE FABRICS

Medical Series Applications: Inflatable Air Mattress, Compression Therapy System, Blood Pressure Gauge

ISO 10993 biocompatibility standard

Medical inflatable materials are often used in the inflatable tube strips of medical mattresses. The pump and microcomputer are used to make the tubular airbag maintain the cycle of inflation and deflation, thereby achieving the effect of massaging muscles and dispersing the contact pressure of the skin by alternate inflation. For patients who need to stay in bed for a long time, to reduce the problem of bedsores, the medical inflatable materials we provide have passed the ISO 10993 biocompatibility standard for medical applications, which can avoid adverse reactions caused by human contact.

Design for a wide parameter

Our medical inflatable material is designed with suitable coating thickness and softness under the combination of plain weave fabric and TPU coating, so that the composite material can achieve good tensile strength and tear resistance/ Ultrasonic/ high-frequency welding method, improve production efficiency and product standardization and reduce labor costs.

Wide applications

These functional materials are widely used in medical or sports protection, such as anti-decubitus air mattresses, inflatable pressure relief cushions, anti-varicose veins, sphygmomanometers, tourniquets, ice packs, anti-lactic acid accumulation compression designs, inflatable tractor, etc.

With the increasing emphasis on environmental protection issues, more and more countries require less DMF use. Nam Liong is developing the non-solvent laminated process that remains the high-bonding performance. As a ESG company, Nam Liong invite you to go green together.

The combination of inflatable materials can be customized according to the demand of customers. Before delivery, the material will be tested and approved by the QC Dept. You are welcome to leave a message below or call +886-6-2420633, let us further discuss and evaluate the product that suits you.

Features

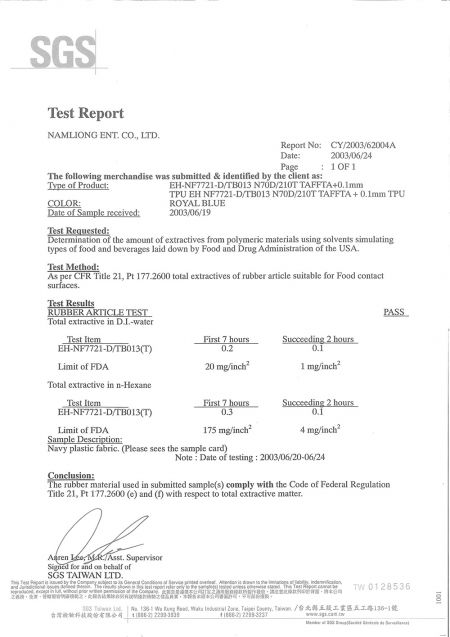

- FDA Test Report

- Strength Test: ASTM D413-98 (2013)

- ISO 10993-5 In vitro cytotoxicity and agar diffusion test

- ISO 10993-10 Skin sensitization study

- ISO 10993-10 White rabbit skin irritation test

Specification

- Full lamination.

- Fabric: Nylon and Poly 40D- 1680D

- MEMBRANE: Polyester base TPU/ Polyether base TPU

- The combination of inflatable materials can be customized according to the demand of customers.

Order Information

- Package:By rolls after OQC process

Applications

- Pressure therapy systems, inflatable protective pads, Anti-decubitus air mattresses, Blood pressure gauge

Gallery

- FDA TEST

- ASTM D413-98(2013)

- ISO 10993-5 AGAR DIFFUSION TEST CONCLUSION

- ISO 10993-10 Skin Sensitization Study CONCLUSION

- ISO 10993-10 white rabbit skin irritation CONCLUSION

- Related Products

Inflatable Device Materials for Water Activities

DetailsApplication: Water sport inflatable device such as Buoyance bag, Dry bag, Air Bag, BCD for diver, Banana boat , Motorboat, Inflatable Kayak, The Floating Shoal Tent

Outdoor / Inflatable materials for outdoor products

Outdoor Series Applications: Camping/ Outdoor Air-Mattress, Motorcycle Air Bag, Hydration Bladder, Dry Bag, Inflatable seat and pillow, water and oil Tank, Food Container

Outdoor inflatable materials are the most widely used materials in outdoor leisure equipment....

DetailsThe ISO-certified material for inflatable life jacket

DetailsThe ISO Certified Inflatable Life Jacket Material, Inflatable Life Vest Material

MEDICAL INFLATABLE FABRICS - Medical Theory System | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including MEDICAL INFLATABLE FABRICS, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.

貼合強度測試.jpg?v=cfa2eb1e)