Eco-friendly Full Bonding Processes

TPU membrane lamination, environmentally friendly adhesion, fabric lamination

Environmentally friendly PUR lamination is widely applied in the manufacturing of functional products. When weather conditions or the surrounding environment change, a functional jacket equipped with this technology can provide reliable protection—offering properties such as moisture permeability, breathability, insulation, and resistance to wind and water.

To demonstrate Nam Liong International's commitment to ESG principles and environmental sustainability, our PUR lamination process incorporates eco-friendly TPU membranes and reactive polyurethane (PUR). Compared to conventional adhesives, this solution is not only more environmentally responsible but also provides stronger initial bonding strength. Once fully cured, it delivers high durability and superior bonding performance. Our production process uses no organic solvents and emits no volatile organic compounds (VOCs), ensuring it is non-toxic and safe. This green lamination technology offers a balance of high functionality, environmental protection, and energy efficiency—aligning with global sustainability goals and enhancing brand value.

PUR lamination technology not only offers a green production process with zero VOC emissions, but also enhances the hand feel of laminated products. When applied to plain or knitted fabrics with functional films, it delivers a soft, comfortable texture. For elastic fabrics, it retains flexibility after lamination, making it an ideal choice for functional jackets and performance garments.

In addition to PUR lamination, we also offer a variety of membrane and fabric processing options, including PU lamination, TPAE lamination, TPEE lamination, PTFE lamination, and microporous membrane lamination. These services allow us to meet a wide range of application needs across different industries. All materials are thoroughly tested by our quality assurance team before shipment to ensure consistent quality and performance. To explore the most suitable solution for your products, please feel free to leave a message below or contact us directly at 06-2420633. We look forward to discussing your requirements in more detail.

Features

- Solvent-free, 100% solid content

- High adhesive strength performance

- Resistance to both water resistance and hydrolysis

- Chemical resistance

- Heat and cold resistance

- Excellent resistance to yellowing

- Ease of processing and no drying required

- Complies with green production standards; manufacturing process is pollution-free

- Manufactured without organic solvents, ensuring zero VOC emissions.

- Offers a superior tactile feel compared to full-surface lamination, while maintaining flexibility in the final product. (Suitable for elastic fabrics)

Specification

- The width is generally below 60”

- Inches for garment types, with a maximum width of up to 63 inches.

- The conventional membrane thickness ranges from 0.015 to 0.02 mm

Order Information

- In standard roll packing

Applications

- Automotive interiors, seating, sunroofs, garments, footwear, bags, home textiles, etc.

- Related Products

PUR Heavy Adhesive Coating

high-strength coating (laminating), environmentally friendly adhesion, fully bonding

PUR fully bonding is a moisture-curing reactive hot melt adhesive (PUR) system that offers...

Details

Eco-friendly Full Bonding Processes - Eco-friendly Full Bonding Processes | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

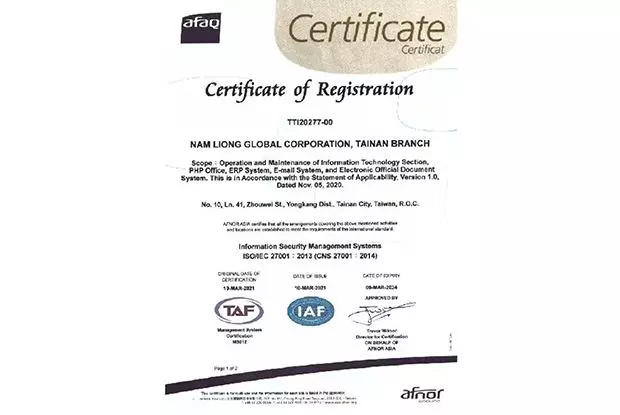

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including Eco-friendly Full Bonding Processes, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.