High Stretchable Abrasion Coated Resistant Fabric Made with Kevlar® Nylon

Model No. KN-601

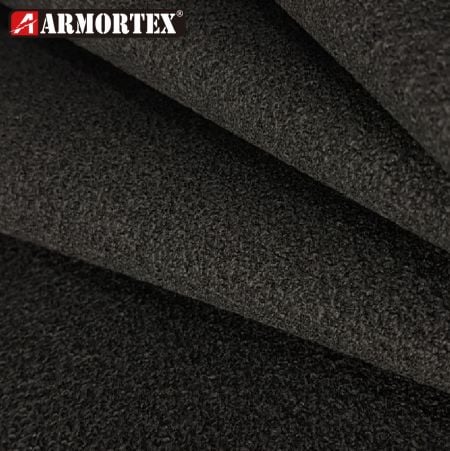

Kevlar® Abrasion Resistant Fabric

This ARMORTEX® woven abrasion-resistant fabric is Dupont Kevlar® and Nylon blended. Additionally, KN-601 also consists of Spandex which delivers stretchability, and its front side is reinforced with black coating to increase the durability (withstand minimum 2500 cycles under ASTM D3886 & perform level 4 under EN388 6.1) Standard.

Based on the EN 17092:2020 certification for motorcycle protective clothing, KN-601 meets the AAA Zone 3 level for high-weight impact abrasion. This makes it an excellent choice for motorcycle and highway riding apparel, delivering an ideal mix of safety, comfort, and style.

Applications

- Partial Reinforcement, Elbow & Knee Protection, Motorcycle Apparel, Safety Gloves.

Specification

- Model No.: KN-601

- Weight: 630gsm, Width: 42"

- Composition: Kevlar®, Nylon, PU

- Abrasion Resistance: 2500 Cycles (ASTM D3886), Level 4(EN 388)

- Test Standard: Compliant With EN 388 And ASTM D3884 D3886

- Abrasion test results are for reference only; many factors can impact fabric durability and appearance.

Order Information

- MOQ: Production MOQ depends on the item and specification demands but generally 300-500 meters per order. No MOQ is required if you select from ready stock.

- Lead time: Depends on the item, lead time could be 5-8 weeks from the date of confirmation of the order, except in the event of greige stock-out (stated lead times are for information purposes only and are not legally binding).

- Payment: We preferred Electronic Funds Transfer to our bank account. Documentary Collections, Letters of Credit payments may be accepted only upon prior approval by Nam Liong Global Corporation,Tainan Branch.

- Packaging: In standard roll packing

Gallery

- stretch coated abrasion resistant fabric KN-601

- stretch coated abrasion resistant fabric KN-601

- stretch coated abrasion resistant fabric KN-601

Nam Liong Story

Running Shoes Client Looking For Lightweight. Abrasion-Resistant. Eco-Friendly Fabric To Bring Out The Best In Kevlar®

Nam Liong has been supplying technical Kevlar®-filled fabrics to the client for years. At the beginning it was fabric purchase orders for the tongue, and then the upper part of the shoe. Net zero emission fabric production has become a social responsibility for today's brands, thus, the client required a non-toxic production process. That includes the usage of eco-friendly additives and solutions, recycled and biodegradable materials, mild chemicals when making anti-splashing fabrics, and so on.

- Files Download