SPECIAL PROCESSING

Water repellent processing, laminating processing, coating processing

Special Water-Repellent Treatment

Our special water-repellent treatment utilises environmentally friendly C6/C0-based agents, developed in line with green manufacturing principles. This treatment not only imparts effective water-repellent properties to the fabric but also enhances PUR bonding performance, improves the appearance after lamination, and increases fabric strength.

According to AATCC 22 testing, even after 10 washes, the treated fabric maintains a water repellency rating of level 3—demonstrating excellent durability and water resistance. This significantly enhances the functionality and added value of the final textile product.

Environmentally Friendly Water-Repellent Solutions

Environmental protection has become an increasingly important focus in recent years, with growing awareness across industries about the environmental impact of perfluorinated chemicals. In response to this concern, we offer two types of water-repellent solutions for customers to choose from.

The first is a C6 low-carbon, environmentally friendly water repellent that provides both oil and water repellency. Thanks to its oil-repellent properties, it is suitable for a broader range of applications while still delivering excellent water resistance.

The second option is a C0 fluorine-free water repellent, developed as a sustainable alternative to traditional C8 and C6 finishes. This latest-generation, non-fluorinated solution fully complies with the EU's stringent ban on perfluorinated compounds (PFCs) and meets the highest global standards for green manufacturing processes.

Special Coating Processing

Our special coating processing technology involves applying a polymer-based compound to the fabric surface to enhance its performance and durability. We use non-toxic, environmentally friendly coating materials that do not cause pollution during production.

This treatment serves multiple purposes: it prevents surface adhesive exposure, minimises yarn shifting, and reinforces fabric strength. Additionally, it can impart specialised functions such as abrasion resistance, waterproofing and breathability, stain resistance, and anti-slip properties.

Applications include functional jackets, casual wear, windbreakers, snowsuits, and camping equipment. A silicone coating option is also available. When applied to the fabric surface, silicone reduces surface friction, making it ideal for medical products that require ease of handling and transport.

Special Lamination Processing

Our special lamination processing uses a coating method combined with Nam Liong’s proprietary fire-resistant adhesive. This technique allows aluminium foil to be laminated as an outer insulating layer, effectively blocking heat sources and radiant heat.

The resulting laminated fabric provides excellent thermal insulation and protection against direct burns in high-temperature environments. It is designed to safeguard the wearer during hazardous operations involving extreme heat, offering both physical protection and peace of mind.

Fire-Resistant Lamination Solutions with PTFE

Fire-resistant fabrics are often used in high-temperature environments, where maintaining comfort is essential. To address this need, Nam Liong has developed fire-resistant fabrics and fire-resistant non-woven materials, laminated with breathable PTFE membranes. Nam Liong is one of the few manufacturers in Taiwan capable of performing lamination processing on fire-resistant fabrics with PTFE membranes.

By leveraging the properties of PTFE microporous membranes, these fire-resistant fabrics offer excellent waterproof and breathable performance. This allows moisture and sweat to be effectively released, ensuring wearer comfort even under intense working conditions.

These materials are ideal for use in fire-resistant linings, high-temperature protective clothing, welding gloves, and safety helmet linings. In 2021, Nam Liong’s fire-resistant non-woven fabric laminated with PTFE successfully passed the ISO 15025 test, confirming its flame-retardant performance.

We offer custom processing based on the required thickness or specific material combinations as requested by our customers. All materials undergo thorough quality assurance testing before shipment to ensure consistent and reliable performance.

For further discussion or to arrange product testing tailored to your needs, please feel free to leave a message below or contact us directly at 06-2420633. We look forward to supporting your product development.

Order Information

- Packaging: In standard roll packing

Applications

- Garments, home textiles, sports protection gear, knee supports, abrasion-resistant gloves, medical protective equipment, sphygmomanometers components

- Related Products

Eco-friendly Full Bonding Processes

TPU membrane lamination, environmentally friendly adhesion, fabric lamination

Environmentally friendly PUR lamination is widely applied in the manufacturing of functional...

Details

SPECIAL PROCESSING - SPECIAL PROCESSING | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

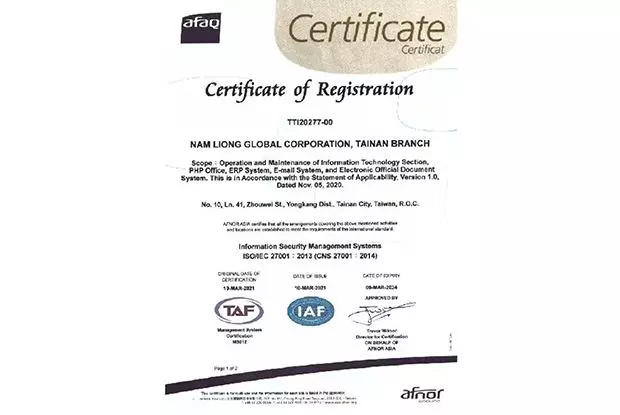

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including SPECIAL PROCESSING, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.