TPEE MEMBRANE

TPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

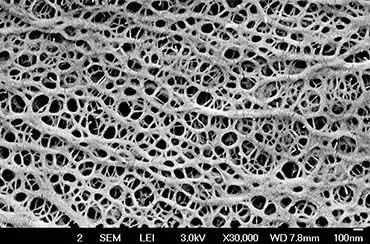

With the rise of fast fashion, millions of tonnes of used clothing each year become difficult to recycle due to mixed materials, leading to significant resource waste and environmental pollution. In recent years, 98% of fibres used are synthetic, with 95% being polyester. Synthetic fibres can only be recycled through chemical processes that require high-quality raw materials. Typically, pre-sorting and cleaning are essential to avoid compromising decomposition efficiency and the quality of recycling.

In addition, polyester membrane is often referred to as PES in the market. However, this abbreviation is also used for a different polymer, polyethersulfone (PES), so extra care should be taken when identifying or selecting materials to avoid confusion or incorrect usage.

In line with the growing trend towards green and sustainable development, Nam Liong’s polyester film offers customers an innovative and eco-friendly solution. This film combines waterproof and breathable properties, effectively preventing external moisture from entering while allowing internal moisture to escape (water vapour resistance < 3 m²/Pa·W), ensuring dryness and comfort for the user.

This makes it the ideal choice for outdoor clothing such as raincoats, functional jackets, and tents. Nam Liong uses TPEE (thermoplastic polyester elastomer) as the base material, which contains no harmful substances such as PVC. Furthermore, no solvents are used in the manufacturing process, significantly reducing emissions of volatile organic compounds (VOCs). This supports environmentally responsible production and has earned certification from bluesign® – a globally recognised standard for sustainable textile manufacturing.

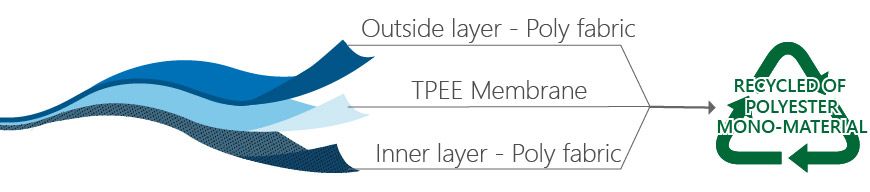

Mixed-material products must have their components separated or stripped before they can enter the recycling process. This is both challenging and costly, which is why these synthetic garments often end up as waste. Nam Liong’s single-material solutions, such as TPAE films bonded to nylon fabrics or TPEE films bonded to polyester fabrics, effectively solve the problem of mixed-material recycling, enabling products to be directly integrated into the recycling process and promoting resource sustainability.

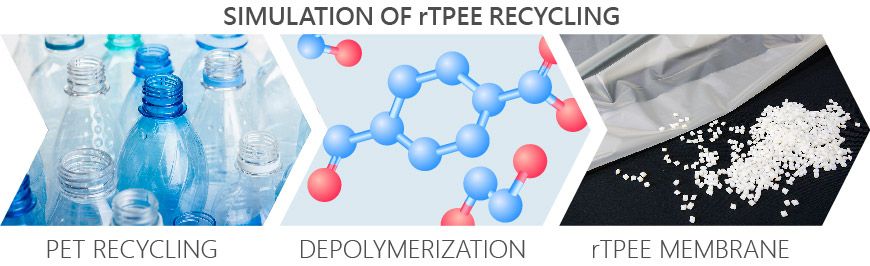

SIMULATION OF rTPEE RECYCLING

In addition to TPEE film, Nam Liong has developed a new eco-friendly material, “rTPEE,” to further promote resource recycling and reuse. This product is created by chemically depolymerising recycled polyester materials (rPET) and reintroducing the depolymerised monomers into the TPEE polymerisation process. Compared to traditional petroleum-based raw materials, rTPEE significantly reduces carbon emissions during production, while maintaining the same excellent physical properties as TPEE, making it a highly promising eco-friendly material.

With the passage of California’s “Textile Recycling Responsibility Act” at the end of 2024, the global fashion industry is facing new challenges regarding material sustainability and recycling responsibilities. As polyester (POLY) is the most widely used material in fashion and outdoor products, its recycling has become increasingly important. Nam Liong’s TPEE series films, combined with polyester fibres, achieve a single-material design, making it easier for products to enter the recycling system and be remanufactured in a circular process. This provides customers with an efficient and sustainable solution.

The single-material solution not only meets the market’s demand for a circular economy, enhances the product’s added value and environmental image, but also reduces the excessive consumption of Earth’s resources by utilising recycled materials. Nam Liong looks forward to collaborating with you to lead the industry towards sustainable development and contribute to global resource reuse and environmental protection.

Nam Liong attaches great importance to the needs of each customer. Please call 06-2420633 immediately, and we will serve you with professional technology. Alternatively, leave a message below to tell us your needs, and let us arrange exclusive consultations and product testing for you to seize the opportunity for your product development! Act now and join hands with Nam Liong to create competitive products!

TPEE Film Feature

UREAMAX® | |

Without PE carrier | |

Feature | |

With PE carrier | |

Feature | |

Feature | |

*S: Clear(matt) color, WS: White color. | |

Applications

- Functional jackets, tents, outdoor and aquatic products

- Related Products

TPU MEMBRANE

Thermoplastic Polyurethane Resin, Waterproof And Moisture-Permeable Film, Eco-Family

UREAMAX® TPU film is made of thermoplastic polyurethane, an environmentally friendly material,...

DetailsMICROPOROUS MEMBRANE

Microporous Breathable PP Film, Polyethylene

The microporous film is breathable by imitating the perspiration of the human body. There are as many...

DetailsBIO-BASED MEMBRANE

BioBased TPU Film, Thermoplastic Polyurethane TPU, GRS Certified Film, Thermoplastics, Environmentally Friendly Film, Eco-Family, BIO TPEE

ECOMATE® biofilm integrates COVATION DuPont's Susterra® biomass-derived materials into its product...

DetailsGRS CERTIFIED MEMBRANE

GRS Certified Film , Global Recycle , Environmentally Friendly Film, Eco-Family

Global Recycled Standard (GRS) is an international, voluntary, and complete product standard...

Details- Files Download

TPEE MEMBRANE - Non-Porous Hydrophilic Thermoplastic Polyester Elastomer Membrane | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

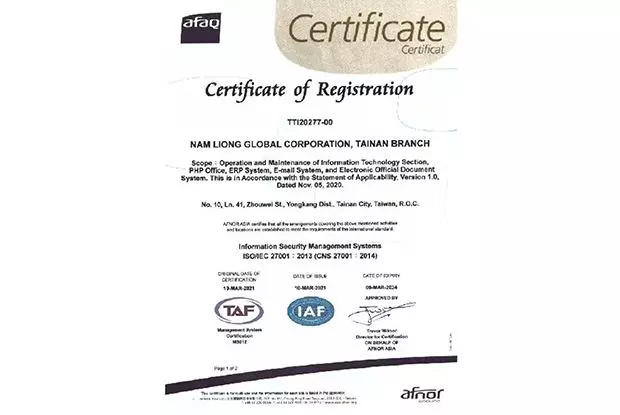

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including TPEE MEMBRANE, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.