TPU MEMBRANE

Thermoplastic Polyurethane Resin, Waterproof And Moisture-Permeable Film, Eco-Family

UREAMAX®

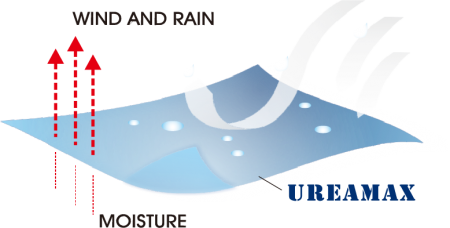

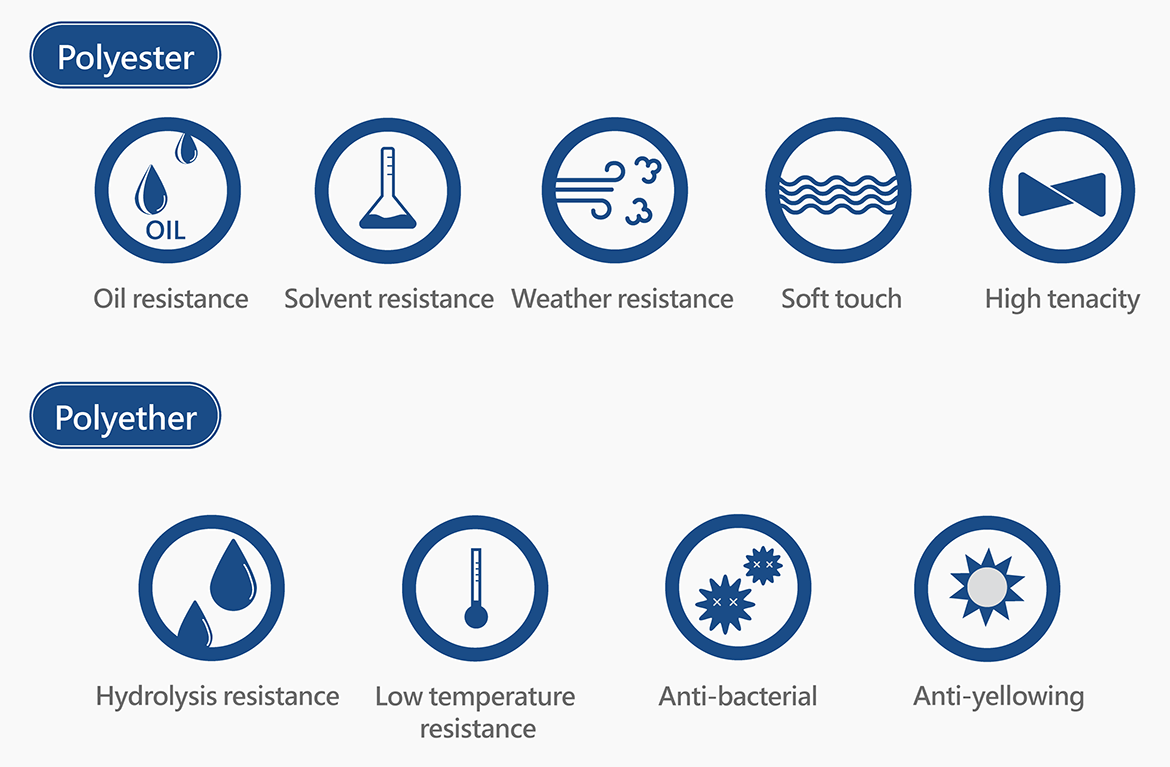

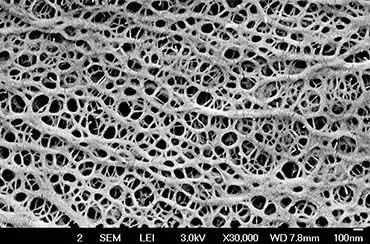

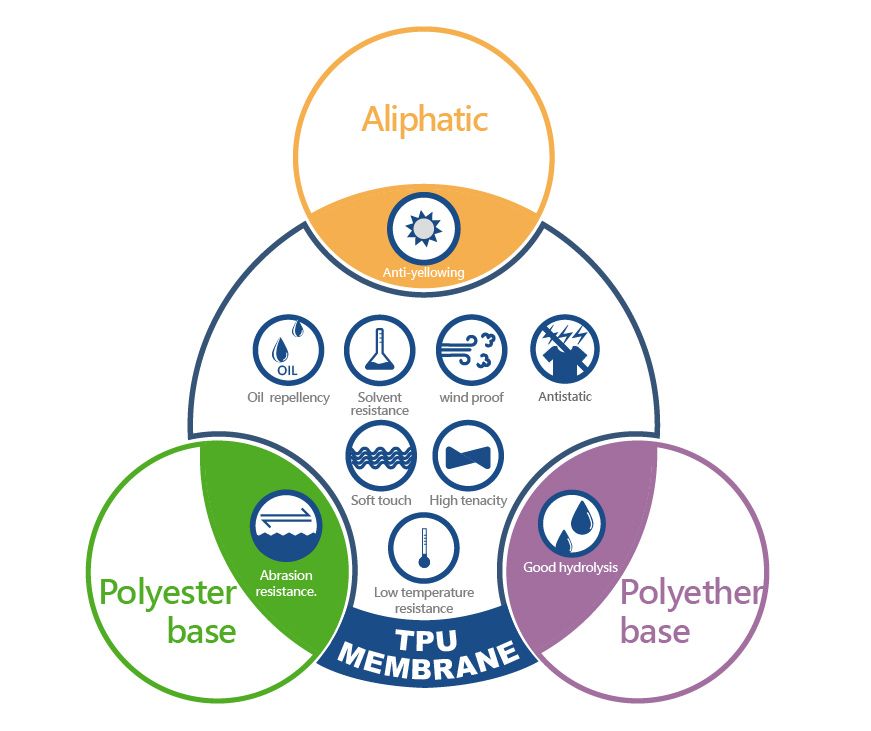

UREAMAX® TPU film is made of thermoplastic polyurethane, an environmentally friendly material, and its main properties are moisture permeability, wind resistance and water resistance. In addition, TPU film can also be divided into polyester type (Polyester) and polyether type (Polyether), because of their differences in strength, durability and ductility, they are also widely used in various functional product markets. Polyester is usually used to make products with high ductility requirements, and can use lamination technology to make functional clothing or mattresses; polyether has hydrolysis resistance and other characteristics, it is mostly used as a raw material for making water sports products and shoes.

Highly moisture-permeable film-the best choice for garments. Both environmental friendly and functionality

Why is the high moisture permeability film favored by ready-to-wear products? Firstly, its high-standard performance can bring better comfort to functional ready-made clothes.

Secondly, TPU is an environment-friendly material in line with the current international demand for green, less pollution and damage to the environment. Compared with DMF-contained PU, TPU can achieve the purpose of sustainable and green proposals.

High moisture permeability films are mostly used for Functional ready-to-wear products, such as soft-shells, windbreakers, protective clothing, bicycle and heavy motorcycle jackets, etc.It is also used in footwear products, such as, waterproof socks, functional shoe materials, etc.

Low moisture permeability films

Low and medium-low moisture permeability films are commonly used in home textiles and industrial products, such as: cleaning pads, bedspreads, quilt covers, pillow covers, sofa fabrics, curtains, tablecloths, inflatable sleeping pads, waterproof bags, hot and cold compress bags, water Bags, cushions, waterproof and dustproof covers for vehicles, etc.

Super light film

Namliang can produce a special light & thin 0.06mm TPU film. In addition, the film itself has excellent moisture-permeable and waterproof properties, which allows the down to reduce moisture absorption and deformation, thus maintaining the comfort of clothing. It is very suitable for fabrics used in down jackets. processing. In addition, Namliong also provides fabric lamination processing services to ensure the perfect combination of film and fabric. If you are interested in this special film and its processing with fabrics, please feel free to contact us and we will be happy to provide you with relevant information and support.

Wide width film

Nam liong is one of the few manufacturers in Taiwan capable of producing wide-format films. Not only can they address the home textile market (including bedding and furniture), but they can also provide products in 105-inch widths to meet diverse customer needs. Namliong is well recognized in the market for its unique capabilities and high-quality products, providing customers with a wider range of choices and winning a good reputation. We also offer special light and thin TPU films to meet customer application requirements, such as down jackets and laminated light fabric. If you are interested, please consult

TPU FILM FEATURE

| Ester base | Ether base | |

| Description | Good tear resistance | Great hydrolysis resistance |

| Feature | 1.Waterproof breathable,windproof , great chemical resistance and easy clean 2.Oil repellency 3.Soft touch 4.Strong abrasion resistance 5.Low temperature resistance |

|

| Application | ‧Garment ‧Home-textile ‧Camping ‧Medical |

‧Medical ‧Water sports ‧Dry bag ‧Shoe |

Product Collections

|

UREAMAX® |

|||||||

|

Low breathable series (Without PE carrier ) |

|||||||

|

Feature: |

|||||||

|

Feature: |

|||||||

|

Feature: |

|||||||

|

• Water proof shoe lining |

|||||||

|

Feature: |

|||||||

|

Feature: |

|||||||

|

Breathable series (With PE carrier) |

|||||||

|

Feature: |

|||||||

|

Feature: |

|||||||

|

*F:Clear/ S:Translucent/WS:White color. |

|||||||

Polyester And Polyether Film Feature

Description of bluesign Certification and UREAMAX®

Applications

- Ester base:Garment、Home-textile、Camping、Medical

- Ether base:Medical、Water sports、Dry bag、Shoe

- Related Products

-

TPEE MEMBRANE

DetailsTPEE Environmental Friendly Film, Thermoplastic Polyester Elastomer, Eco-Family, PES Membrane

MICROPOROUS MEMBRANE

Microporous Breathable PP Film, Polyethylene

The microporous film is breathable by imitating the perspiration of the human body. There are as many...

DetailsBIO-BASED MEMBRANE

BioBased TPU Film, Thermoplastic Polyurethane TPU, GRS Certified Film, Thermoplastics, Environmentally Friendly Film, Eco-Family, BIO TPEE

ECOMATE® biofilm integrates COVATION DuPont's Susterra® biomass-derived materials into its product...

DetailsGRS CERTIFIED MEMBRANE

GRS Certified Film , Global Recycle , Environmentally Friendly Film, Eco-Family

Global Recycled Standard (GRS) is an international, voluntary, and complete product standard...

Details - Files Download

TPU MEMBRANE - UREAMAX® | Made in Taiwan Textile Fabric Manufacturer with ESG Reports | Nam Liong

Located in Taiwan since 1972, Nam Liong Global Corporation,Tainan Branch has been a high-tech, functional, environment-friendly textiles and foam composite materials manufacturer. Their main textile products, including TPU MEMBRANE, Neoprene, Industrial-Use Rubber Sponge, TPU Film, Inflatable, Hook And Loop, Abrasion Resistant Fabric, Flame Retardant Fabric, Cut Resistant Fabric, Anti Slip Fabric, Functional Yarn and Products, which meet international standards such as USDA and bluesign.

Nam Liong Global Corporation,Tainan Branch provides high-tech, functional, environment-friendly polymers and high elastic foam materials to meet all kinds of requirements from our customers with our continuous R&D ability and great service quality. With more than 45 years of experience, Nam Liong is dedicated to environmental protection and keeps developing eco-friendly products in compliance with international environmental regulation. Following the concept of respect for life, we focus on the development of products for health protection to avoid potential hazards to human body.

Nam Liong has been offering customers functional fabric and bio-based neoprene sponge, both with advanced fabric technology and 50 years of experience, Nam Liong ensures each customer's demands are met.